Industrial monitoring has evolved dramatically over the past decade. Organizations across utilities, agriculture, manufacturing, and environmental sectors now demand continuous visibility into remote assets without the burden of constant maintenance. Enter the NB-IoT data logger IP67, a breakthrough technology that combines years of battery life with reliable cellular connectivity and industrial-grade sensors.

What is a Data Logger: The Foundation of Remote Monitoring

A data logger is an electronic device that automatically records measurements from sensors over time. Unlike manual data collection that provides occasional snapshots, data loggers capture continuous information, temperature, pressure, humidity, flow rates, or any measurable parameters, storing it locally or transmitting it to cloud platforms for analysis.

Traditional data loggers required physical retrieval to download stored data. Modern connected data loggers, particularly NB-IoT data loggers, transmit information wirelessly over cellular networks, enabling real-time monitoring from anywhere.

Key Components of Modern Data Loggers

Every data logger consists of four essential elements:

Sensors or sensor interfaces measure physical parameters. Industrial NB-IoT data loggers typically include 4-20 mA analog inputs, the standard interface for thousands of industrial sensor types including pressure transducers, level sensors, flow meters, and temperature transmitters.

Data processing units convert sensor readings into digital values. Microcontrollers like the STM32L072 perform analog-to-digital conversion, apply calibration factors, and prepare data for transmission or storage.

Memory storage buffers readings during network outages. MicroSD cards provide expandable storage ensuring no data loss even when cellular connectivity temporarily fails.

Communication interfaces transmit data to monitoring systems. This is where NB-IoT data loggers excel, using cellular networks specifically designed for IoT applications.

What Makes NB-IoT Different: Understanding Narrowband IoT Technology

Narrowband IoT (NB-IoT) represents a Low Power Wide Area Network (LPWAN) technology purpose-built for IoT devices. Unlike traditional cellular networks optimized for smartphones and high-speed data, NB-IoT data logger systems prioritize three critical factors: power efficiency, coverage, and cost.

Power Efficiency: The 5+ Year Battery Life Advantage

NB-IoT modems consume dramatically less power than traditional cellular technologies. While 2G or LTE-M modules draw 200-300 mA during transmission, NB-IoT operates at 150-220 mA with superior power-saving modes. Combined with ultra-low-power microcontrollers, NB-IoT data loggers achieve 5-7 years of operation on primary batteries.

This efficiency stems from intelligent duty cycling. The device sleeps in ultra-low-power mode (consuming just 2 µA) for 99.9% of operational time. It wakes only to take sensor readings and transmit batched data at scheduled intervals. For example, hourly sensor sampling with 6-hour upload cycles, battery life extends beyond traditional expectations.

Extended Coverage: Reaching Remote Locations

NB-IoT provides 20 dB better link budget compared to traditional GSM networks. This enhanced signal penetration enables NB-IoT data loggers to function in challenging environments, deep inside buildings, underground installations, or remote rural locations where conventional cellular signals fail.

For utilities monitoring remote tank farms, agricultural operations tracking soil moisture across vast acreage, or environmental agencies measuring water quality in wilderness areas, this extended coverage proves essential.

Cost Optimization: Lower Infrastructure and Operating Expenses

NB-IoT networks require minimal data transmission. Most NB-IoT data logger applications transmit just 200-500 bytes per reading. At this rate, monthly data usage typically remains under 50 KB, enabling cost-effective IoT data plans as low as $2-5 per month compared to traditional cellular plans costing $20-50 monthly.

How Battery-Powered NB-IoT Data Logger IP67 Integrate with Industrial Sensors

Industrial environments have standardized on 4-20 mA current loops for sensor communication. This analog interface offers exceptional noise immunity, works reliably over long cable runs, and provides a clever diagnostic feature: 4 mA represents the minimum measurement while 0 mA indicates a broken wire or failed sensor.

The 4-20 mA Current Loop Explained

Industrial sensors convert physical measurements into proportional current output. A pressure sensor rated for 0-100 PSI outputs 4 mA at 0 PSI and 20 mA at 100 PSI, with linear scaling between. The NB-IoT data logger measures this current using precision sense resistors, typically 120Ω, creating a voltage proportional to the current.

Modern NB-IoT data loggers include integrated 12V excitation supplies powering two-wire sensors directly. This eliminates external power requirements, simplifying installation and reducing component count.

Real-World Integration Example

Consider a water utility monitoring remote tank levels. A submersible pressure transducer at the tank bottom measures hydrostatic pressure proportional to water depth. The sensor’s 4-20 mA output connects directly to the NB-IoT data logger’s analog input terminals.

The logger samples pressure hourly, converts readings to tank level using calibration factors, and batches six readings for transmission every six hours. Cloud software receives the data, displays real-time levels on dashboards, and triggers SMS alerts when levels approach critical thresholds.

Total installation time: 30 minutes. Maintenance required: zero for 5+ years.

Key Advantages of Battery-Powered NB-IoT Data Logger IP67

Deployment Flexibility

No electrical infrastructure required. NB-IoT data loggers operate entirely on battery power, enabling installation anywhere cellular coverage exists. Remote wellheads, agricultural fields, environmental monitoring sites, or distributed utility infrastructure, all become accessible monitoring locations.

Weather-Resistant Reliability

Industrial-grade NB-IoT data loggers feature IP67-rated enclosures providing complete dust protection and water immersion resistance. Operating temperature ranges from -40°C to +85°C ensure functionality across extreme climates, from arctic conditions to desert heat.

Field testing across diverse environments validates this durability. Deployments in Montana winters (-25°C), Arizona summers (+45°C), and tropical humidity (100% RH) demonstrate consistent performance without weather-related failures.

Maintenance-Free Operation

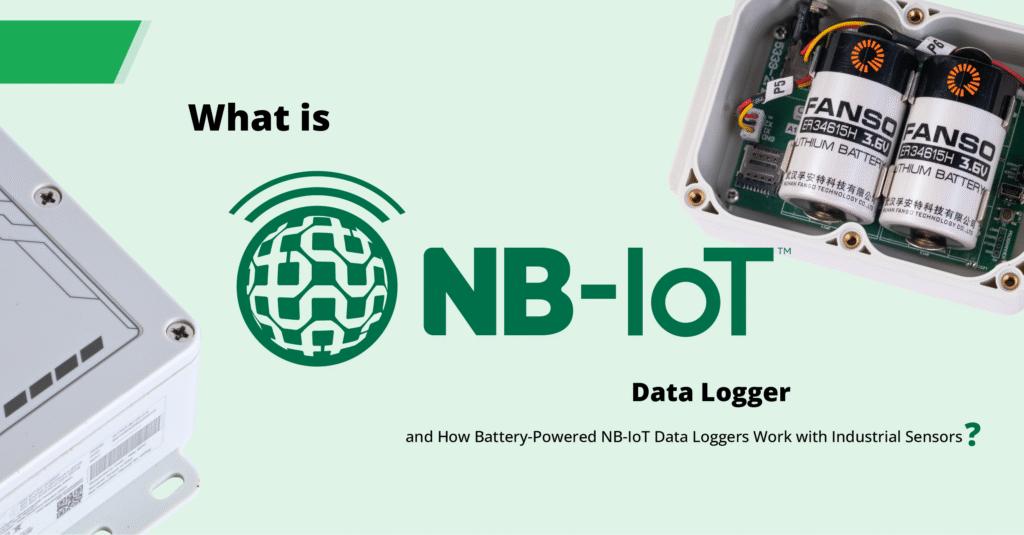

Five to seven years without site visits represents a transformative operational improvement. Traditional monitoring requires quarterly or monthly battery replacements. NB-IoT data logger technology with high-capacity lithium thionyl chloride batteries (38,000 mAh typical) eliminates this maintenance burden entirely.

For organizations monitoring 50+ remote sites, this translates to thousands of eliminated site visits and hundreds of thousands in saved operational costs over the device lifetime.

Multi-Network Resilience

Advanced NB-IoT data loggers support multiple cellular technologies, NB-IoT, Cat-M1, and 2G fallback. Automatic network selection ensures connectivity as carriers upgrade infrastructure and retire legacy networks. This future-proofs investments protecting against technology transitions.

Practical Applications Across Industries

Water and Wastewater Utilities

Municipal utilities monitor tank levels, pump station performance, pressure zones, and flow meters across distributed infrastructure. NB-IoT data loggers provide continuous visibility replacing manual weekly checks. One cooperative monitoring 47 remote tanks achieved $180,000 annual savings through eliminated site visits while preventing overflow incidents through early alerts.

Precision Agriculture

Farmers optimize irrigation using soil moisture data from NB-IoT data loggers connected to moisture sensors. Real-time measurements enable precision watering—applying water only when and where crops need it. Deployments demonstrate 25% water savings while improving yields through optimal moisture management.

Environmental Monitoring

Government agencies and research institutions track water quality, air pollution, and climate conditions through distributed sensor networks. NB-IoT data loggers enable long-term monitoring in sensitive ecosystems without frequent human disturbance. Continuous data reveals patterns impossible to detect through periodic manual sampling.

Oil and Gas Operations

Upstream and midstream operations monitor wellhead pressure, tank farm levels, and pipeline conditions across remote locations. NB-IoT data loggers provide visibility into assets distributed over vast geographic areas with minimal infrastructure, enabling predictive maintenance and early problem detection.

Technical Specifications That Matter

When evaluating NB-IoT data logger solutions, several specifications determine real-world performance:

Battery capacity directly determines operational lifetime. Look for 38,000 mAh capacity supporting 5+ years at hourly sampling intervals. Lithium thionyl chloride chemistry provides optimal energy density and temperature performance.

Cellular network support should include NB-IoT plus Cat-M1 or 2G fallback ensuring connectivity across different carriers and geographic regions. Multi-band support enables global deployment flexibility.

Environmental rating must match deployment conditions. IP67 minimum for outdoor installations, with operating temperature ranges covering local climate extremes. UV-stabilized enclosures resist years of solar exposure.

Sensor compatibility determines application breadth. Dual 4-20 mA inputs with integrated sensor power support the widest range of industrial sensors without additional signal conditioning.

Data security protects sensitive operational information. TLS/SSL encryption, secure boot, and X.509 certificates ensure only authorized parties access sensor data.

Implementing NB-IoT Data Logger Solutions: Best Practices

Site Survey and Coverage Validation

Before deployment, verify NB-IoT coverage at installation locations. Network coverage maps provide initial guidance, but field testing with actual equipment confirms signal strength. Marginal locations benefit from external antenna mounting improving reception 5-10 dB.

Sensor Selection and Calibration

Choose sensors appropriate for measured parameters and environmental conditions. Verify 4-20 mA output compatibility and power requirements. Perform two-point calibration, applying known minimum and maximum values, recording actual readings, then calculating scaling factors ensuring accuracy.

Power Budget Planning

Calculate expected battery life based on actual duty cycles. Account for temperature effects, battery capacity decreases 10-15% at temperature extremes compared to room temperature ratings. Include safety margins ensuring devices remain operational beyond projected replacement intervals.

Cloud Platform Integration

Select IoT platforms supporting MQTT, HTTP, or CoAP protocols for broad NB-IoT data logger compatibility. Configure data visualization dashboards, alert rules, and notification methods during initial setup. Test alert delivery before final deployment confirming operators receive critical notifications.

The Future of NB-IoT Data Logger Technology

NB-IoT networks continue expanding globally as carriers recognize IoT market potential. 5G infrastructure deployment includes NB-IoT support ensuring long-term technology viability. NB-IoT data logger manufacturers leverage these improvements delivering enhanced capabilities.

Emerging developments include edge computing enabling local data processing and anomaly detection before transmission. Machine learning algorithms identify unusual patterns triggering immediate alerts rather than waiting for scheduled uploads. Energy harvesting from solar, thermal, or vibration sources supplements battery power potentially enabling indefinite operation in suitable environments.

Integration with digital twin platforms creates virtual representations of physical assets. Continuous data from NB-IoT data loggers keeps digital models synchronized with real-world conditions enabling sophisticated simulation and optimization.

Making the Decision: Is an NB-IoT Data Logger Right for You?

NB-IoT data loggers excel when applications require:

- Remote locations without electrical infrastructure

- Multi-year deployment without maintenance access

- Modest data volumes (periodic sensor readings)

- Industrial sensor compatibility (4-20 mA interfaces)

- Weather-resistant outdoor operation

- Cost-effective long-term monitoring

Organizations monitoring distributed assets, utilities, agricultural operations, environmental networks, or industrial facilities, consistently achieve strong return on investment through eliminated site visits, prevented failures, and operational optimization enabled by continuous data visibility.

The technology has matured beyond early adoption into proven, reliable solutions deployed across thousands of installations worldwide. Real-world performance validates manufacturer claims: 5+ year battery life, 99%+ uptime, and dramatic operational cost reductions.

Take the Next Step

Ready to implement NB-IoT data logger monitoring for your remote assets? Start with a pilot deployment at 3-5 representative locations. Test actual performance under your specific conditions validating battery life, connectivity, and data quality before full-scale rollout.

The NORVI EC-M12-BC-C6-C-A NB-IoT data logger exemplifies modern industrial monitoring technology: 38,000 mAh battery capacity, IP67 weatherproof protection, multi-network cellular support, and dual 4-20 mA industrial sensor inputs proven across 150+ real-world deployments.

Explore technical specifications, review case studies, or request an evaluation unit to experience the operational transformation continuous remote monitoring delivers.