The renewable energy sector continues to demand advanced monitoring solutions that deliver real-time insights and predictive analytics. Consequently, solar installations require robust IoT gateways to track performance, optimize efficiency, and prevent costly downtime. This comprehensive guide demonstrates how to build an industrial-grade solar monitoring gateway with IoT using the NORVI X controller platform.

Understanding Solar Monitoring Gateway Architecture

What Is a Solar Monitoring Gateway?

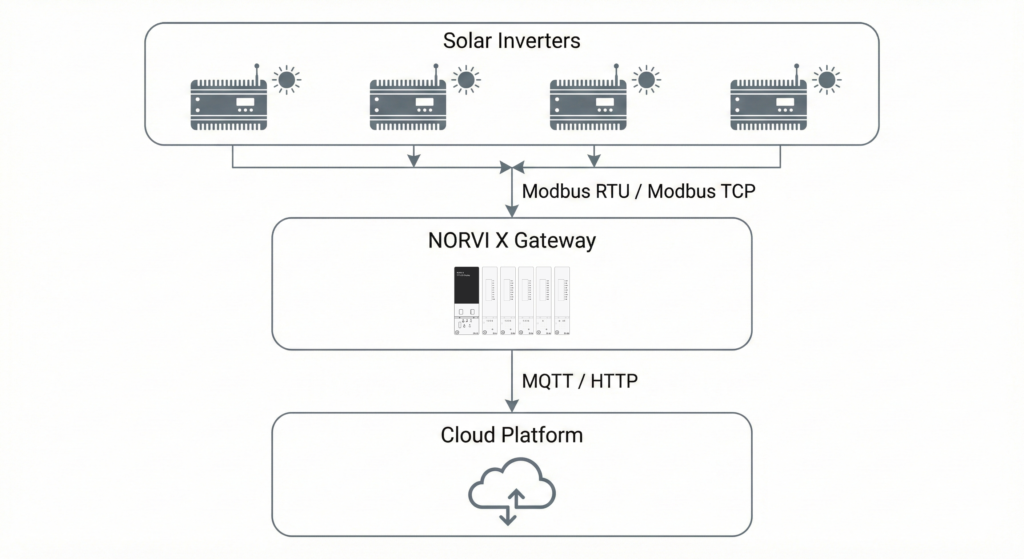

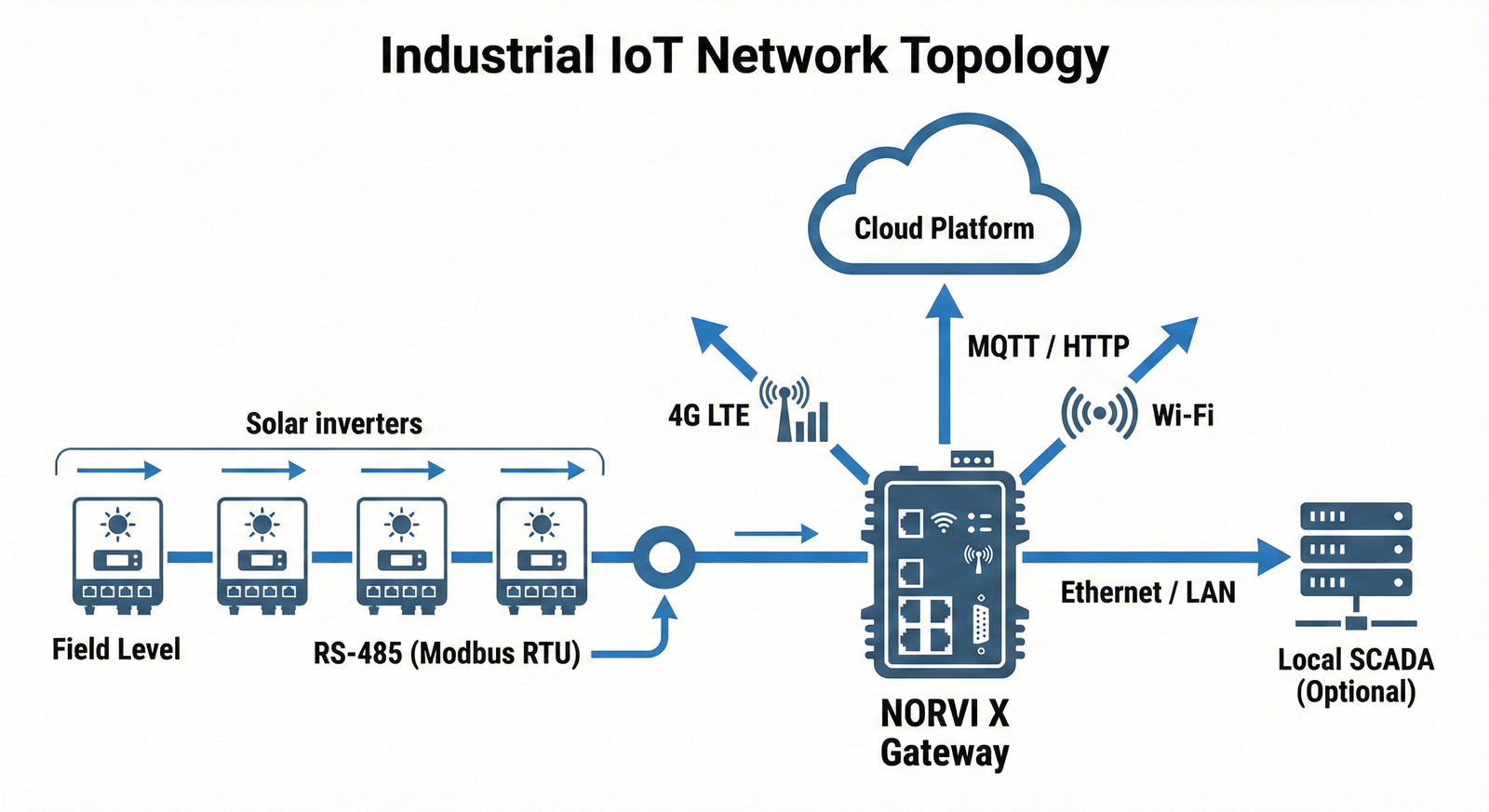

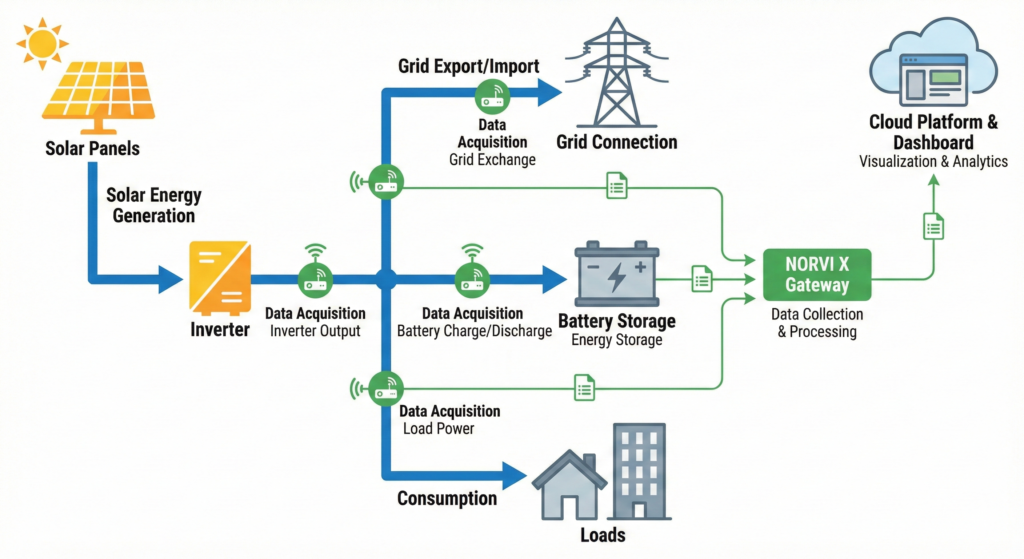

A solar monitoring gateway serves as the central communication hub between solar inverters, sensors, and cloud platforms. Essentially, this device collects data from multiple sources, processes information locally, and transmits critical metrics to remote monitoring systems. Please refer to the following image for a visual understanding of the system architecture.

Furthermore, modern gateways enable bidirectional communication, allowing operators to control and optimize solar installations remotely.

Industrial IoT solar panel monitoring systems typically include several key components. First, the gateway connects to inverters through industrial protocols like Modbus RTU or Modbus TCP. Subsequently, it aggregates data from environmental sensors measuring irradiance, temperature, and weather conditions. Finally, the system transmits processed information to SCADA systems or cloud platforms for analysis and visualization.

Why IoT Technology Transforms Solar Monitoring

Traditional solar monitoring solutions often rely on proprietary systems with limited scalability and high costs. In contrast, IoT-based approaches offer remarkable flexibility and cost-effectiveness. Moreover, IoT solar energy solutions enable predictive maintenance, reducing operational expenses by up to 30%.

The integration of ESP32-based controllers revolutionizes solar monitoring implementations. These powerful microcontrollers provide dual-core processing, extensive connectivity options, and low power consumption. Additionally, they support multiple communication protocols simultaneously, making them ideal for complex industrial applications.

NORVI X: The Ultimate Industrial IoT Controller for Solar Applications

Technical Specifications and Capabilities

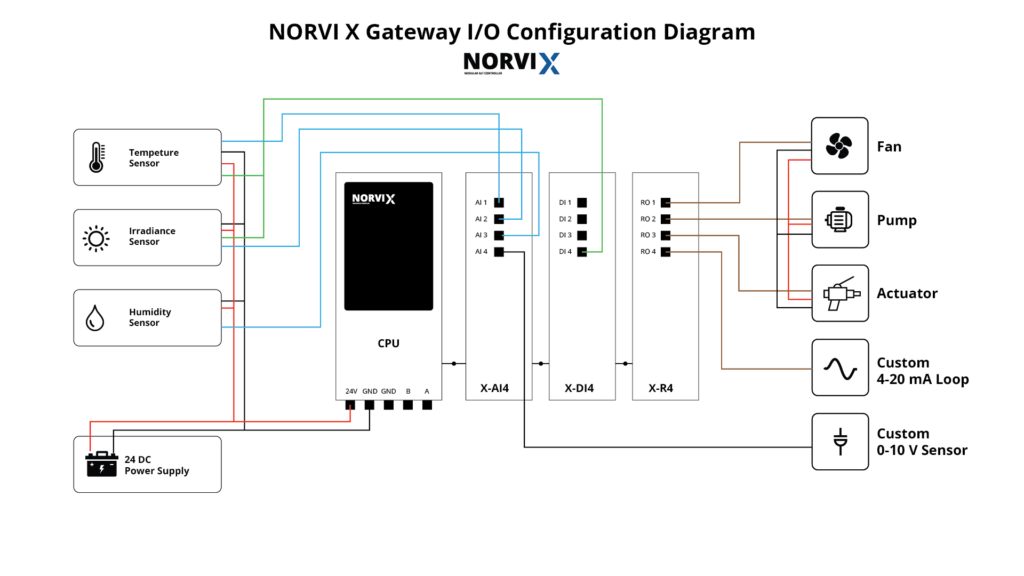

The NORVI X controller represents a next-generation platform specifically designed for industrial IoT applications. Built around the ESP32-S3 processor, this device delivers exceptional performance in demanding environments. Furthermore, its modular architecture allows engineers to customize I/O configurations based on specific requirements.

Key technical features include multiple communication interfaces. Specifically, the controller offers RS485 Modbus communication for direct inverter connectivity. Similarly, it provides Ethernet ports supporting Modbus TCP protocols. Additionally, WiFi and Bluetooth enable wireless connectivity for installation flexibility. For remote solar farm monitoring, optional 4G LTE modules ensure reliable data transmission even in isolated locations.

The scalable I/O architecture supports digital inputs, analog inputs, relay outputs, and transistor outputs. Consequently, engineers can monitor up to 200 I/O points across multiple expansion modules.

This scalability proves essential for large-scale photovoltaic monitoring systems requiring comprehensive data acquisition.

Industrial-Grade Reliability for Harsh Environments

Solar installations face extreme environmental conditions including high temperatures, humidity, and electrical noise. Therefore, monitoring gateways must maintain reliable operation under these challenging circumstances. The NORVI X platform incorporates industrial-grade components rated for extended temperature ranges from -40°C to +85°C.

Moreover, the DIN-rail mounting system facilitates professional installation within electrical enclosures. The robust design protects sensitive electronics from moisture, dust, and electromagnetic interference. Subsequently, this reliability translates to reduced maintenance costs and extended system lifespan.

Implementing Modbus Solar Inverter Monitoring

Understanding Modbus Protocol in Solar Applications

Most modern solar inverters communicate using Modbus protocols, making this the industry standard for real-time solar analytics. Modbus RTU operates over RS485 serial communication, while Modbus TCP utilizes Ethernet networks. Consequently, the NORVI X controller supports both variants, ensuring compatibility with diverse inverter manufacturers.

The protocol enables gateways to query inverters for critical parameters including instantaneous power output, cumulative energy production, voltage levels, current measurements, and operational status codes. Furthermore, advanced implementations can retrieve detailed diagnostic information, enabling proactive maintenance strategies.

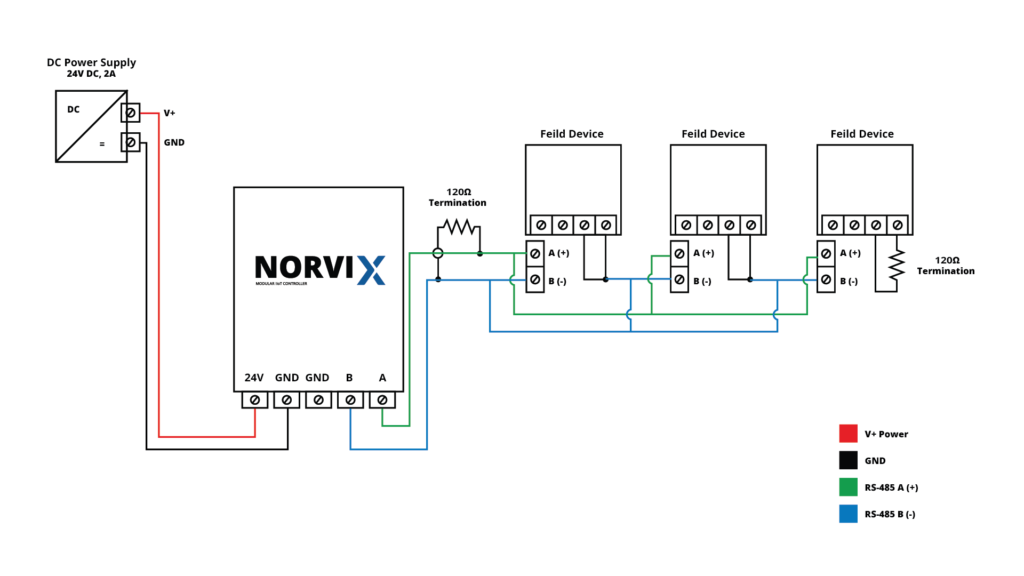

Configuring RS485 Modbus Communication

Setting up Modbus communication requires careful attention to electrical specifications and protocol parameters. First, engineers must connect the RS485 terminals correctly, observing proper polarity between A+ and B- lines. Additionally, termination resistors should be installed at both ends of the bus to prevent signal reflections as shown in the following diagram.

Next, the configuration involves setting the communication parameters. These typically include baud rate (commonly 9600 or 19200), data bits (8), parity (none or even), and stop bits (1). Moreover, each inverter requires a unique Modbus address, preventing communication conflicts on shared bus networks. In the following diagram shows how NORVI X Read and receives data from slave devices.

The NORVI X controller simplifies this process through its integrated development environment. Engineers can program the ESP32 using Arduino IDE, enabling rapid prototyping and deployment. Subsequently, the flexible programming environment allows implementation of custom data parsing logic tailored to specific inverter models.

Building Cloud-Connected Solar Monitoring Systems

MQTT Protocol Integration for IoT Connectivity

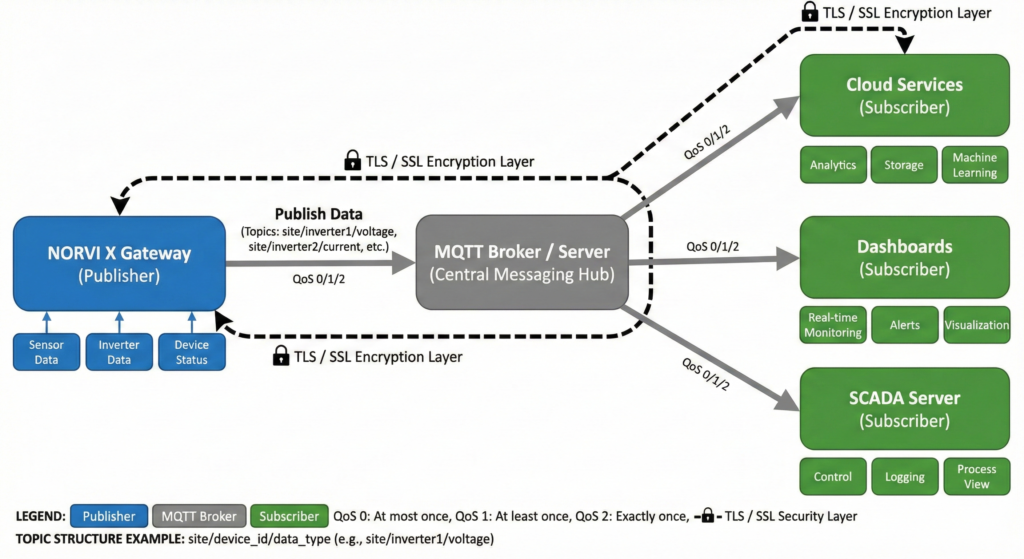

Cloud connectivity transforms local monitoring systems into comprehensive solar asset monitoring platforms. The MQTT protocol has emerged as the preferred choice for IoT applications due to its lightweight nature and efficient bandwidth utilization. Consequently, implementing MQTT enables seamless integration with major cloud platforms including AWS IoT Core, Azure IoT Hub, and Google Cloud IoT.

The publish-subscribe architecture of MQTT provides several advantages. First, it decouples data producers from consumers, enhancing system flexibility. Additionally, quality of service levels ensure reliable message delivery even under poor network conditions. Furthermore, the protocol supports secure communication through TLS encryption, protecting sensitive operational data.

Implementing Real-Time Solar Panel Monitoring

Real-time monitoring requires efficient data collection and transmission strategies. The NORVI X controller can query inverters at configurable intervals, typically ranging from 1 to 60 seconds depending on application requirements. Subsequently, the gateway aggregates data from multiple sources before transmission.

Edge computing capabilities enable local data processing, reducing cloud bandwidth requirements. For instance, the controller can calculate derived metrics such as performance ratios, capacity factors, and efficiency indices. Moreover, local algorithms can detect anomalies and trigger immediate alerts without waiting for cloud processing.

The implementation involves creating data structures that organize information logically. JSON formatting has become standard for IoT data exchange due to its human-readable format and wide platform support. Additionally, structured data enables efficient database storage and facilitates advanced analytics.

Advanced Features for Solar Farm Management

Predictive Maintenance Through Data Analytics

Modern solar monitoring systems extend beyond basic data collection to provide actionable insights. Machine learning algorithms can analyze historical performance data to predict component failures before they occur. Consequently, operators can schedule maintenance proactively, minimizing production losses.

The NORVI X gateway can implement local analytics for immediate decision-making. For example, comparing actual output against expected performance based on irradiance data reveals underperforming panels. Similarly, monitoring string-level currents identifies potential issues with individual panels or connections.

Furthermore, long-term trend analysis reveals degradation patterns that inform replacement strategies. This data-driven approach optimizes capital expenditure by replacing components based on actual condition rather than arbitrary schedules.

Multi-Site Solar SCADA System Implementation

Large solar portfolios require centralized monitoring across multiple installations. The NORVI X controller integrates seamlessly with SCADA systems, providing standardized data interfaces. Consequently, operators can monitor dozens of sites from a single control center.

The hierarchical architecture typically employs local gateways at each site communicating with regional aggregation servers. Subsequently, these servers feed data into enterprise-level SCADA platforms.

This structure balances real-time responsiveness with scalable data management.

Additionally, the system supports role-based access control, ensuring appropriate information visibility for different stakeholders. Plant operators view detailed technical data, while management receives high-level performance summaries and financial metrics.

Practical Implementation Guide

Hardware Setup and Wiring

Beginning the installation requires careful planning of component placement and wiring routes. First, mount the NORVI X controller on DIN rails within the main electrical enclosure. Ensure adequate ventilation and protection from direct sunlight, as excessive heat reduces electronic component lifespan.

Next, connect the RS485 terminals to the inverter communication ports. Use shielded twisted-pair cable rated for industrial environments, maintaining proper cable separation from high-voltage AC circuits. Additionally, ground the cable shields at one end only to prevent ground loops.

Power connections require attention to voltage specifications and current ratings. The NORVI X typically operates on 12-24V DC supplies (Check power details), commonly available in solar installations. Moreover, implementing surge protection devices safeguards the gateway from voltage transients caused by lightning or switching operations.

Software Configuration and Programming

Programming the NORVI X controller involves several sequential steps. Initially, install the Arduino IDE and configure the ESP32-S3 board support package. Subsequently, install necessary libraries for Modbus communication, MQTT connectivity, and data processing.

The core program structure includes initialization routines, periodic data acquisition loops, and communication handlers. First, the system establishes connections to inverters and verifies communication. Then, it enters the main loop where it queries devices, processes data, and transmits information to cloud platforms.

Error handling routines ensure system resilience. For instance, if inverter communication fails, the system should retry with exponential backoff strategies. Similarly, loss of internet connectivity triggers local data buffering until connection restoration.

Testing and Commissioning

Thorough testing validates system functionality before deployment. Begin with bench testing using Modbus simulators to verify communication logic. Subsequently, connect to actual inverters in a controlled environment, confirming correct data interpretation.

Field testing should occur during various operational conditions. Monitor system behavior during startup, normal operation, and shutdown sequences. Additionally, test cloud connectivity under poor network conditions to verify buffering and recovery mechanisms.

Documentation completes the commissioning process. Record all configuration parameters, network settings, and customization details. Furthermore, create operational procedures for routine monitoring and troubleshooting, ensuring long-term system maintainability.

Cost-Effective Industrial Solar Monitoring Solutions

Comparing Traditional vs. IoT-Based Approaches

Traditional solar monitoring relies on proprietary hardware and software, resulting in high upfront costs and vendor lock-in. Conversely, open-source IoT platforms like the NORVI X dramatically reduce expenses while increasing flexibility. The cost difference can reach 60-70% for equivalent functionality.

Moreover, IoT solutions provide superior scalability. Adding monitoring points to traditional systems often requires expensive upgrades, whereas IoT platforms scale incrementally. This flexibility proves especially valuable for growing solar portfolios.

Maintenance costs also favor IoT implementations. Over-the-air firmware updates eliminate site visits for software improvements. Additionally, standardized protocols simplify technician training and reduce troubleshooting time.

Return on Investment Calculations

Implementing comprehensive monitoring delivers measurable financial benefits. Early fault detection prevents production losses that can cost thousands of dollars daily for large installations. Furthermore, optimized maintenance schedules reduce labor costs and extend equipment lifespan.

Performance monitoring enables accurate warranty claims when equipment underperforms. Many inverter manufacturers guarantee specific output levels, and detailed monitoring data substantiates claims for remediation or replacement.

Additionally, granular production data supports accurate financial forecasting and facilitates power purchase agreement compliance. These capabilities enhance the overall value proposition of solar investments.

Future Trends in Solar Energy IoT Solutions

Artificial Intelligence and Edge Computing

The convergence of AI and IoT transforms solar monitoring from reactive to predictive systems. Machine learning models trained on historical data can forecast production with remarkable accuracy. Consequently, grid operators can better manage renewable energy integration.

Edge AI implementations process data locally, reducing latency and bandwidth requirements. The ESP32-S3 processor provides sufficient computational power for inference operations, enabling real-time anomaly detection and autonomous control decisions.

Furthermore, federated learning approaches allow models to improve while preserving data privacy. This technique trains algorithms across multiple installations without centralizing sensitive operational data.

Blockchain Integration for Energy Trading

Emerging peer-to-peer energy trading platforms leverage blockchain technology for transparent, secure transactions. Solar monitoring gateways can automatically participate in these markets, selling excess production when prices favor generation.

Smart contracts execute trades automatically based on predefined rules and real-time production data. This automation eliminates intermediaries, increasing revenue for solar asset owners.

Additionally, blockchain-based systems provide immutable records of energy production and consumption, supporting regulatory compliance and renewable energy certificate management.

Conclusion: Building Your Solar Monitoring Gateway

Implementing an industrial-grade solar monitoring gateway with IoT technology delivers substantial operational and financial benefits. The NORVI X controller provides a robust, flexible platform that meets the demanding requirements of modern solar installations. Its combination of industrial reliability, extensive connectivity options, and open-source programmability makes it ideal for both small-scale and enterprise applications.

By following this comprehensive guide, engineers and system integrators can develop sophisticated monitoring solutions that rival expensive proprietary systems at a fraction of the cost. The technical knowledge shared here empowers teams to customize implementations precisely matching their specific requirements.

As the renewable energy sector continues its rapid growth, advanced monitoring capabilities become increasingly critical. Organizations that invest in comprehensive IoT-based solar monitoring position themselves for competitive advantage through optimized operations, reduced costs, and enhanced reliability.

Start building your solar monitoring gateway today and unlock the full potential of your photovoltaic installations through intelligent, connected monitoring systems.