OEM machine builders face mounting pressure to reduce machine builder cost while delivering smarter, more connected equipment. Traditional PLC-based architectures drive up hardware expenses, extend panel assembly time, and lock manufacturers into costly vendor ecosystems. However, forward-thinking OEMs are now switching to the modular industrial IoT controller NORVI X, achieving up to 60% cost savings without compromising reliability or functionality.

This comprehensive guide explores how the cost to replace PLC with IIoT controller delivers substantial OEM automation cost savings across hardware, engineering, and lifecycle expenses.

The Cost Challenges OEM Machine Builders Face Today

Modern machine builders operate in an increasingly competitive landscape where customers demand Industry 4.0 capabilities at lower price points. Unfortunately, traditional automation architectures create significant cost barriers that impact profitability and market competitiveness.

Rising PLC Hardware and I/O Expansion Costs

Traditional PLCs require separate modules for basic control, I/O expansion, communication gateways, and power supplies. Each component adds to the bill of materials (BOM) and increases procurement complexity. Additionally, proprietary expansion modules from major PLC vendors often cost 2-3 times more than open-platform alternatives, yet manufacturers feel locked into these ecosystems.

When building multiple machine variants, OEMs must stock different PLC models and expansion cards for each configuration. This inventory burden ties up capital and increases the risk of obsolescence.

Panel Wiring, Assembly Time, and Labor Overhead

Complex wiring between discrete components consumes significant panel build time. Engineers spend hours routing cables between PLCs, I/O modules, HMIs, and industrial gateways. Moreover, each connection point represents a potential failure source that requires testing and documentation.

Panel assembly labor costs continue rising, especially in regions with skilled labor shortages. For high-volume machine builders producing dozens of units monthly, these hours translate directly to reduced margins and delayed deliveries.

Licensing Fees and Vendor Lock-In Risks

Many PLC platforms require expensive programming software licenses, often costing $2,000-$5,000 per seat. System integrators and machine builders supporting multiple customer sites face recurring license renewal fees that erode profitability. Furthermore, dependency on proprietary protocols and software creates long-term vendor lock-in, limiting flexibility to adopt new technologies or negotiate better pricing.

Why Traditional PLC-Based Designs Inflate Machine Costs

Understanding the structural cost drivers in conventional automation architectures reveals why many OEMs struggle to compete on price while offering modern connectivity features.

Separate PLC, I/O, Gateway, and Power Modules

Legacy machine designs require distinct components for each function. OEMs purchase a PLC for logic control, add distributed I/O modules for sensor connectivity, install an industrial gateway for cloud communication, and integrate separate power supplies for each subsystem. This fragmented approach multiplies component costs and increases enclosure size requirements.

Each additional module also introduces integration complexity. Engineers spend valuable time configuring communication between devices, troubleshooting protocol mismatches, and validating system behavior.

Limited Scalability for Machine Variants

Customers increasingly expect customized machine configurations tailored to specific production requirements. However, traditional PLC architectures make customization expensive and time-consuming. Adding analog inputs or communication protocols often requires completely different hardware modules, forcing OEMs to maintain extensive inventory.

This inflexibility slows time-to-market for new machine variants and prevents OEMs from quickly responding to customer requests or market opportunities.

High Engineering and Commissioning Effort

Programming PLCs requires specialized expertise and expensive software tools. System validation and commissioning involve testing each hardware module individually, then validating integrated system behavior. Because traditional PLCs lack built-in diagnostic tools and cloud connectivity, remote troubleshooting becomes nearly impossible, necessitating costly field service visits.

What Is NORVI X and Why OEMs Are Adopting It

NORVI X represents a fundamentally different approach to machine control, combining multiple functions into a single modular platform designed specifically for cost-conscious OEM applications.

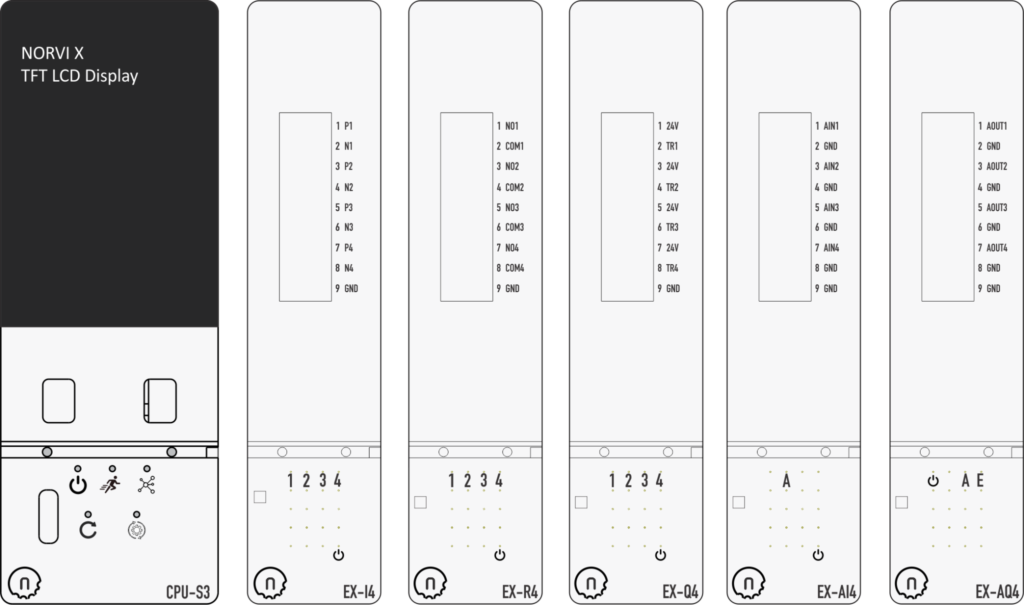

Modular Industrial IoT Controller Architecture

The NORVI X edge controller for machine builders features a powerful ESP32-S3 dual-core processor with built-in WiFi, Bluetooth, and optional 4G LTE connectivity. Instead of purchasing separate devices, OEMs get integrated control, communication, and edge computing capabilities in one DIN-rail mountable unit.

The modular architecture supports up to 200 I/O points through stackable expansion modules. Digital inputs, analog sensors, relay outputs, and specialty modules connect via a standardized internal bus, eliminating complex point-to-point wiring. This scalability allows OEMs to configure exactly the I/O count needed for each machine variant without over-provisioning hardware.

Built-In Industrial Protocols and Edge Computing

NORVI X natively supports Modbus RTU/TCP, MQTT, HTTP/HTTPS, and OPC-UA protocols without requiring additional gateway hardware. The embedded RS-485 port enables direct connection to industrial sensors and drives, while Ethernet provides reliable plant-floor networking.

The ESP32-S3 processor delivers sufficient computing power for edge analytics, data preprocessing, and local decision-making. Machine builders can implement predictive maintenance algorithms, production monitoring dashboards, and cloud data synchronization directly on the controller, reducing dependency on external systems.

Open, Developer-Friendly Ecosystem for OEMs

Unlike proprietary PLC platforms, NORVI X embraces open standards and widely used development tools. Engineers program the controller using Arduino IDE, ESP-IDF, or MicroPython, all free, industry-standard environments with extensive community support and libraries.

This openness eliminates expensive software licensing fees and reduces the learning curve for engineering teams. Developers can leverage thousands of existing code libraries for sensors, communication protocols, and data processing rather than starting from scratch.

Cost Breakdown – How NORVI X Delivers Up to 60% Savings

The financial benefits of switching to NORVI X span multiple cost categories, creating compounding savings throughout the machine lifecycle.

Reduced Hardware BOM (Controller + I/O + Gateway)

NORVI X consolidates controller, communication gateway, and edge computing functions into a single unit. For a typical packaging machine requiring 32 digital inputs, 16 digital outputs, 8 analog inputs, Modbus communication, and cloud connectivity, the hardware cost comparison reveals significant savings:

| Traditional PLC Architecture | NORVI X Architecture |

|---|---|

| Base PLC unit: $800-$1,200 | CPU module with connectivity: $60-$100 |

| Digital I/O modules: $400-$600 | Digital I/O expansion modules: $20-$60 |

| Analog input module: $300-$500 | Analog input expansion: $20-$60 |

| Industrial IoT gateway: $500-$800 | Built-in power management: $0 (integrated) |

| Power supplies & accessories: $200-$300 | |

| Total: $2,200-$3,400 | Total: $100-$220 |

This represents a 90-95% reduction in hardware BOM costs alone, an extraordinary cost advantage that transforms OEM economics. For OEMs building 100+ machines annually, these savings translate to $210,000-$328,000 in recovered margin or competitive pricing power. Even at 50 units per year, manufacturers save $105,000-$164,000 annually on hardware costs alone.

Lower Panel Wiring and Enclosure Size

The modular stackable design dramatically reduces wiring complexity. Instead of routing dozens of cables between separate devices, engineers snap expansion modules directly onto the CPU, with internal bus communication handling all data transfer. This architectural change delivers measurable benefits:

- Panel assembly time reduced by 40-50%: Simple snap-together modules replace complex wiring harnesses

- Smaller enclosure requirements: Reduced footprint allows 20-30% smaller control panels

- Fewer connection points: Integrated design eliminates 50+ wire terminations per machine

For a contract manufacturer building 10 machines monthly, reducing panel assembly from 8 hours to 4.5 hours per unit saves approximately $450 per machine in labor costs (assuming $25/hour loaded rate). Smaller enclosures further reduce material costs by $30-$60 per unit.

No Recurring Software or Licensing Fees

Traditional PLC programming software requires substantial upfront investment and ongoing maintenance:

- Initial license cost: $2,000-$5,000 per engineering seat

- Annual maintenance: $400-$800 per license

- Multi-site deployment: Additional licenses for field service technicians

NORVI X development uses completely free tools, Arduino IDE, Visual Studio Code, and ESP-IDF. A 5-year total cost comparison for a 5-engineer team shows:

Traditional PLC Software:

- Initial licenses: $12,500 (5 × $2,500)

- 5-year maintenance: $10,000 (5 years × 5 licenses × $400)

- Total 5-year cost: $22,500

NORVI X Development Tools:

- All software: $0

- Total 5-year cost: $0

Faster Engineering, Testing, and Deployment

Open-source development accelerates every phase of the product lifecycle. Engineers leverage proven libraries for common tasks like Modbus communication, sensor interfacing, and cloud connectivity rather than developing proprietary solutions. This reduces engineering effort by 30-40% compared to traditional PLC programming.

Remote programming capabilities enable over-the-air firmware updates, eliminating costly field visits for software changes. When customers request feature enhancements or bug fixes, OEMs can deploy updates remotely, improving customer satisfaction while reducing support costs.

Flexibility Advantages for OEM Machine Builders

Beyond direct cost savings, NORVI X’s flexible architecture solves strategic challenges that traditional PLCs cannot address efficiently.

Modular I/O Expansion for Different Machine Models

Product families often require different I/O configurations. A basic conveyor might need 16 inputs and 8 outputs, while an advanced version requires 32 inputs, 16 outputs, and 8 analog sensors. NORVI X’s modular design allows OEMs to use the same CPU across all variants, simply adding the necessary expansion modules for each configuration.

This modularity delivers:

- Reduced inventory complexity: Single CPU platform serves entire product line

- Lower spare parts burden: Common modules across machine variants costing $20-$100 each versus $300-$600 for proprietary PLC modules

- Faster customer customization: Add specialized I/O modules during final assembly

Easy Customization for OEM-Specific Features

Machine builders differentiate through unique features and specialized capabilities. NORVI X’s open firmware architecture enables deep customization that would be impossible or prohibitively expensive with traditional PLCs. OEMs can implement proprietary control algorithms, custom HMI interfaces, specialized data logging, and industry-specific protocols without vendor approval or expensive custom hardware.

The availability of thousands of Arduino libraries accelerates development of advanced features like vision system integration, barcode scanning, GPS tracking, or machine learning inference.

Seamless Cloud, SCADA, and Dashboard Integration

Modern customers expect comprehensive data visibility and remote monitoring capabilities. NORVI X includes built-in MQTT, HTTP/HTTPS, and WebSocket support, enabling direct communication with cloud platforms like AWS IoT, Azure IoT Hub, or custom dashboards.

The controller can host local web interfaces, allowing operators to monitor machine status, adjust parameters, and view diagnostics through any web browser without installing specialized HMI software. This capability transforms how OEMs deliver value—shifting from selling standalone machines to offering connected equipment with ongoing data services.

Real-World OEM Use Cases and Retrofit Scenarios

NORVI X proves its value across diverse industrial applications, from new machine development to legacy equipment modernization.

Packaging and Conveyor Machines

Packaging equipment requires precise timing control, multiple sensor inputs, and integration with upstream/downstream systems. A packaging machine OEM replaced their PLC-based control system with NORVI X and achieved:

- Hardware cost reduction from $2,800 to $180 per machine (93.6% savings)

- Panel assembly time decreased from 6.5 hours to 3.5 hours

- Added remote monitoring and predictive maintenance features without additional gateway hardware

- Enabled customer self-service troubleshooting through web-based diagnostics

For their 150-unit annual production, this generated $393,000 in annual hardware savings alone while improving customer satisfaction and reducing field service calls by 35%.

Material Handling and Logistics Equipment

Automated guided vehicles (AGVs) and material handling systems benefit tremendously from NORVI X’s integrated wireless connectivity. A logistics equipment manufacturer developing a fleet of battery-powered conveyor modules chose NORVI X for several compelling reasons:

- Built-in WiFi eliminated expensive industrial wireless modules ($400-$600 per unit), saving $400+ per system

- Total hardware cost of $150-$200 versus $2,500-$3,200 for traditional PLC-based control (94% reduction)

- Low power consumption extended battery runtime by 20% compared to traditional PLC solutions

- Over-the-air updates allowed continuous improvement of navigation algorithms across deployed fleet

- Cloud data logging enabled predictive battery replacement, reducing unplanned downtime

Legacy PLC Machine Modernization

Many OEMs support installed machine bases using discontinued PLC models with expensive spare parts and limited support. Retrofitting legacy equipment with NORVI X provides a cost-effective modernization path.

A food processing equipment manufacturer developed a retrofit kit replacing aging PLCs in their 15-year-old machines. The NORVI X solution:

- Maintained all existing I/O connections through compatible expansion modules

- Added Ethernet and cloud connectivity absent in original design

- Enabled remote monitoring and troubleshooting capabilities

- Reduced spare parts inventory requirements by 60%

- Extended machine lifespan by 10+ years at 1/3 the cost of complete replacement

Customers appreciated gaining modern features without replacing functioning equipment, while the OEM generated new revenue from retrofit kit sales and remote monitoring subscriptions.

When NORVI X Is the Right Choice for OEMs

While NORVI X delivers impressive benefits, understanding ideal use cases ensures successful implementation and maximum value realization.

High-Volume Machine Production

OEMs producing 50+ units annually gain maximum advantage from NORVI X’s lower per-unit hardware costs and faster assembly time. The cumulative savings justify the engineering investment required to transition from traditional PLC platforms.

For small batch or custom machine builders producing fewer than 20 units yearly, the engineering conversion effort might exceed short-term savings. However, these builders still benefit from reduced software licensing costs and easier customization capabilities.

Cost-Sensitive Markets and SMEs

Small and medium manufacturers building equipment for cost-sensitive industries—food processing, agriculture, small-scale manufacturing—find NORVI X particularly compelling. The dramatically lower BOM cost allows competitive pricing while maintaining healthy margins.

Emerging market OEMs competing against established manufacturers use NORVI X to undercut competitor pricing by 15-25% while offering equivalent or superior functionality, particularly regarding connectivity and data capabilities.

Machines Requiring IoT and Remote Monitoring

Equipment operating in distributed locations—agricultural machinery, construction equipment, environmental monitoring systems, requires robust remote connectivity. NORVI X’s built-in cellular and Wi-Fi capabilities eliminate the need for separate industrial gateways costing $500-$1,000.

The integrated architecture simplifies deployment, reduces failure points, and enables sophisticated edge computing scenarios impossible with traditional gateway-based approaches.

Frequently Asked Questions

NORVI X meets industrial-grade specifications including wide operating temperature ranges (-10°C to +85°C), ESD protection up to 8kV, shock resistance to 15g, and optically isolated I/O. Components comply with IEC 61131-2 and EN 61010-1 standards, ensuring reliability comparable to established PLC brands.

The base controller handles standard control functions reliably. For safety-critical operations requiring SIL certification, OEMs typically implement dedicated safety PLCs or safety relays for emergency stop circuits while using NORVI X for primary control and data acquisition functions.

NORVI provides comprehensive datasheets, example code, connection diagrams, and technical documentation. The large ESP32 developer community offers extensive resources, forums, and libraries. Direct technical support assists with hardware selection, integration questions, and troubleshooting.

Engineers familiar with Arduino or C/C++ programming adapt quickly to NORVI X development. For teams experienced only in ladder logic, expect a 2-4 week learning curve. However, the extensive Arduino ecosystem and available code examples significantly accelerate development compared to proprietary PLC programming environments.

Unlike proprietary PLC platforms, NORVI X uses widely available standard components, ESP32 processors, common I/O expanders, and standard communication chips. This reduces obsolescence risk significantly. If specific modules are discontinued, engineers can design compatible replacements using reference designs and standard components.

Conclusion – Building Cost-Efficient, Future-Ready Machines

Summary of Cost and Flexibility Benefits

The transition from traditional PLC architectures to the modular industrial IoT controller NORVI X delivers proven OEM automation cost savings across multiple dimensions:

Financial Benefits:

- 90-95% reduction in hardware BOM costs (from $2,200-$3,400 down to $100-$220)

- Elimination of software licensing fees saving $20,000-$30,000 per 5-year period

- 40-50% reduction in panel assembly labor

- 20-30% smaller enclosure requirements reducing material costs

Operational Advantages:

- Modular scalability supporting product family variations

- Seamless cloud and SCADA integration without additional gateways

- Over-the-air firmware updates reducing field service costs

- Open development environment accelerating engineering cycles

Strategic Capabilities:

- Deep customization enabling proprietary features and differentiation

- Competitive pricing advantage in cost-sensitive markets

- Modern connectivity meeting Industry 4.0 customer expectations

- Reduced vendor lock-in providing long-term flexibility

Why NORVI X Is a Strategic PLC Alternative for OEMs

Machine builders face intensifying pressure to deliver smarter equipment at lower prices. Traditional PLC-based architectures simply cannot meet these dual demands – their fragmented design, proprietary ecosystems, and high component costs fundamentally limit competitiveness.

NORVI X represents more than a component substitution. It enables a architectural shift toward integrated, connected, flexible machine designs that reduce costs while expanding capabilities. By consolidating controller, communication gateway, and edge computing functions into a single modular platform, OEMs eliminate unnecessary complexity and expense.

The open development environment democratizes access to industrial control, allowing smaller machine builders to compete with established players. Free programming tools, extensive community resources, and standard protocols lower barriers to entry while accelerating innovation.

For OEMs seeking to reduce machine builder cost 60% while delivering Industry 4.0 capabilities, NORVI X provides a proven, reliable path forward. The combination of lower hardware costs, faster assembly, eliminated licensing fees, and enhanced flexibility creates sustainable competitive advantage in an increasingly challenging market.

Ready to reduce your machine builder costs? Contact NORVI to discuss your specific application and receive detailed cost analysis comparing your current architecture to NORVI X solutions.

Download the complete NORVI X technical specifications and selection guide to begin evaluating retrofit opportunities for your existing machine designs.