|

Phone: +94 77 111 1776

|

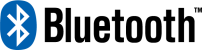

ESP32 Based HMI Controller

ESP32 based HMI controller with 5-inch touch display for industrial automation

Price: $137.50

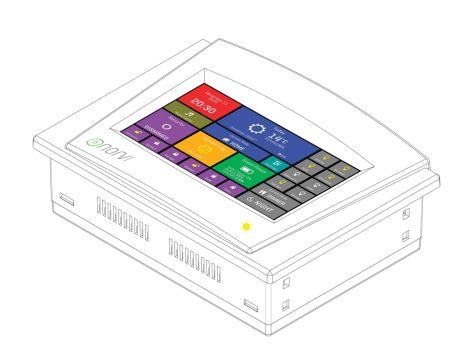

ESP32 Based HMI Controller delivers powerful automation capabilities for modern industrial applications. This programmable HMI controller combines an ESP32-WROOM32 processor with a built-in 5-inch resistive touchscreen display. Therefore, it provides seamless integration for IoT projects and PLC operations. Furthermore, the device supports LVGL graphics library and Arduino programming, making it accessible for both beginners and professionals.

The industrial esp32 hmi controller offers comprehensive connectivity through WiFi, Bluetooth, Ethernet, and RS-485 communication. Additionally, it features analog inputs, digital inputs, and transistor outputs in a compact DIN-rail mountable package.

Feature Highlights

- ESP32 S3 Integration with

- 8MB PSRAM

- 5inch LCD Display with

- Resistive Touch

- LVGL Technology

- Built-in Buzzer

- Digital Inputs

- Analog Inputs

- Transistor Outputs

- Supports Industrial Voltage up to 24V DC

- Arduino Compatibility

- PLC functionality

Models: ESP-HMI-5C-CI | ESP-HMI-5C-VI

- Worldwide Shipping Available

Key Features of ESP32 HMI Controller

Processing Power & Display

- ESP32-WROOM32 Core Processor — Delivers robust performance with 520KB SRAM and 4MB flash memory.

- 5-Inch Resistive Touch Display — Provides clear visualization and intuitive user interaction for automation control.

- LVGL Graphics Support — Enables smooth, modern UI development for professional industrial applications effortlessly.

Connectivity Options

- Dual-Band WiFi & Bluetooth – Connects wirelessly to networks and devices for flexible deployment scenarios.

- W5500 Ethernet Module – Ensures stable, wired network communication for critical automation systems reliably.

- RS-485 Communication – Facilitates industrial protocol integration with existing automation infrastructure and legacy systems.

Input & Output Capabilities

- Digital Inputs 24V – Monitors sensor states and switch positions for comprehensive system awareness.

- 4-20mA Analog Inputs – Reads precision sensor data from temperature, pressure, and flow transmitters.

- Transistor Outputs – Controls low-power devices like indicators, solenoids, and small motors efficiently.

- 0-10V Analog Inputs – Accepts standard voltage signals from industrial sensors and variable frequency drives.

Industrial Applications for ESP32 Touch HMI

Manufacturing Process Control

Monitor and control production lines using the esp32 arduino hmi with real-time data visualization capabilities. Consequently, operators gain instant feedback on machine performance, quality metrics, and production efficiency through the touchscreen interface.

Building Automation Systems

Manage HVAC controls, lighting systems, and access control through the ethernet rs485 hmi integration. Moreover, the programmable hmi esp32 enables energy monitoring and optimization across multiple zones simultaneously.

Agricultural Monitoring Solutions

Track environmental conditions including temperature, humidity, and soil moisture with 4-20mA analog inputs. Additionally, automated irrigation control responds to sensor data, conserving water while maintaining optimal growing conditions.

Remote Equipment Monitoring

Oversee distributed assets via Wi-Fi connectivity and cloud integration through the esp32 automation controller. Furthermore, receive alerts and control equipment remotely from anywhere with internet access.

Processor & Memory

- MCU: ESP32-WROOM32 dual-core processor

- Flash Memory: 4MB for program storage

- ROM: 448KB internal memory

- SRAM: 520KB for runtime operations

Display Specifications

- Screen Size: 5-inch diagonal display

- Touch Technology: Resistive touchscreen

- Graphics Library: LVGL supported

- Interface: SPI communication protocol

Power Requirements

- Rated Voltage: 24V DC input

- Current Draw: 400mA typical operation

- Recommended PSU: 1A 24V DC supply

Digital Inputs

- Quantity: 4 channels

- Voltage Range: 18-32V DC

- Input Type: Sink and source compatible

- Max Frequency: 1kHz switching rate

Transistor Outputs

- Quantity: 4 channels

- Type: Open collector/drain configuration

- Max Current: 100mA per channel

- Max Voltage: 40V DC

- Switching Speed: 1kHz maximum

Physical & Environmental

- Mounting: DIN-rail or mounting tabs

- Dimensions: 90.5 × 60.6 × 56.6mm

- Enclosure: Industrial-grade housing

- IP Rating: IP20 protection

- Temperature: -10°C to +85°C operating

- Humidity: 0-95% non-condensing

- Altitude: 0-2000m operational

Additional Features

- RTC Module: DS3231 real-time clock with battery backup

- microSD Card: Expandable storage for data logging

- Buzzer: Built-in audio feedback

- Programming: Arduino IDE compatible

Analog Inputs: Available in Two Configurations

4-20mA Current Inputs (Model: ESP-HMI-5C-CI)

- Quantity: 4 channels

- Current Range: 4-20mA loop-powered

- Resolution: High-precision ADC conversion

- Application: Industrial transmitters and sensors

0-10V Voltage Inputs (Model: ESP-HMI-5C-VI)

- Quantity: 4 channels

- Voltage Range: 0-10V DC

- Input Impedance: High impedance for accurate readings

- Resolution: 12-bit ADC precision

- Application: Voltage output sensors and transducers

Communication Interfaces

RS-485 Serial

- Mode: Half-duplex communication

- Transceiver: MAX485 chip

- Protocols: Modbus RTU compatible

- Flow Control: GPIO4 direction pin

Ethernet Connectivity

- Controller: W5500 chipset

- Speed: 10/100 Mbps capability

- Protocols: TCP/IP, UDP, MQTT

Wireless Connectivity

- WiFi: 2.4GHz 802.11 b/g/n

- Bluetooth: Classic and BLE support

- Range: Standard indoor/outdoor coverage

Why Choose This HMI Controller with Display

Comprehensive Development Support

Arduino IDE compatibility accelerates development cycles with extensive libraries and community support available. Moreover, LVGL graphics framework simplifies creating professional-looking interfaces without deep embedded graphics knowledge required.

Flexible Connectivity Architecture

Multiple communication protocols enable integration with diverse automation ecosystems and legacy systems seamlessly. Furthermore, simultaneous WiFi, Ethernet, and RS-485 operation provides redundant connectivity paths for mission-critical applications.

Industrial-Grade Reliability Standards

Wide temperature range operation ensures consistent performance in harsh industrial environments and challenging conditions. Additionally, DIN-rail mounting and IP20 enclosure meet standard panel installation requirements universally.

Cost-Effective Automation Solution

Integrated display, processor, and I/O reduce total system costs compared to separate component solutions. Therefore, faster deployment and lower installation expenses improve overall project economics significantly.

Frequently Asked Questions

Yes, the esp32 hmi controller integrates with standard PLCs through RS-485 Modbus RTU protocol communication. Additionally, Ethernet connectivity enables integration with networked automation systems using industrial protocols.

The controller primarily uses Arduino C/C++ programming through Arduino IDE for straightforward development. Furthermore, ESP-IDF framework provides advanced capabilities for experienced developers requiring lower-level control.

Choose between two models based on sensor type: ESP-HMI-5C-CI for 4-20mA current loop sensors or ESP-HMI-5C-VI for 0-10V voltage sensors. Both provide four analog input channels with built-in scaling functions to convert readings into engineering units.

The ESP-HMI-5C-CI features 4-20mA current inputs for industrial transmitters and loop-powered sensors. Meanwhile, the ESP-HMI-5C-VI offers 0-10V voltage inputs suited for position sensors, humidity transmitters, and variable frequency drive feedback signals.

The resistive touchscreen operates reliably in dusty, wet conditions and works with gloved hands. Additionally, the industrial-grade display withstands temperature extremes from -10°C to +85°C operational range.

Yes, the expansion port supports additional I/O modules for digital inputs, relay outputs, and analog channels. Therefore, system capacity scales easily to meet growing application requirements without controller replacement.