Introduction to Industrial Energy Meter Monitoring

Industrial facilities face mounting pressure to reduce energy costs and improve sustainability. Consequently, real-time energy meter monitoring systems have become essential for competitive operations. Traditional manual meter readings no longer suffice in today’s data-driven manufacturing environment.

Modern industrial operations demand comprehensive visibility into power consumption across multiple machines, production lines, and building systems. Furthermore, regulatory compliance requirements like ISO 50001 necessitate documented energy management systems with accurate historical data.

This guide explores how NORVI X transforms industrial energy monitoring through its modular ESP32-based architecture. We’ll examine complete system design from RS-485 connected energy meters through edge processing to cloud dashboards, demonstrating why NORVI X delivers superior results for manufacturing facilities, OEMs, and system integrators.

Why Real-Time Energy Monitoring Matters in Industry

Every manufacturing facility experiences hidden energy waste. Equipment running during idle periods, inefficient motors, and unmanaged peak demand create unnecessary costs. Real-time monitoring transforms this situation by providing immediate visibility into consumption patterns.

Smart energy monitoring systems enable facility managers to identify issues instantly rather than discovering problems weeks later through utility bills. Additionally, continuous data collection supports:

- Immediate detection of equipment malfunctions through abnormal power patterns

- Strategic demand management to avoid expensive peak charges

- Data-driven scheduling of production around energy costs

- Accurate allocation of energy costs across departments

Industries implementing comprehensive monitoring typically reduce energy consumption by 10-20% within the first year. Moreover, documented energy data satisfies ISO 50001 certification requirements and supports energy audits.

Limitations of Traditional Energy Monitoring Approaches

Legacy monitoring systems create substantial operational challenges. Manual meter readings demand regular site visits, proving impractical for facilities with dozens or hundreds of monitoring points. Similarly, standalone meters with local displays provide no centralized visibility or analytical capabilities.

Traditional SCADA systems often require expensive proprietary hardware and lack modern cloud connectivity. They also demand specialized programming skills and offer limited flexibility for expansion. Furthermore, retrofitting existing facilities with conventional monitoring infrastructure involves significant wiring costs, system downtime, and integration complexity.

These limitations explain why forward-thinking facilities are adopting edge-based IoT monitoring architectures built on platforms like NORVI X.

Key Components of an Energy Monitoring System

Understanding complete system architecture begins with identifying each essential component. Every element plays a specific role in capturing, processing, and presenting energy data effectively.

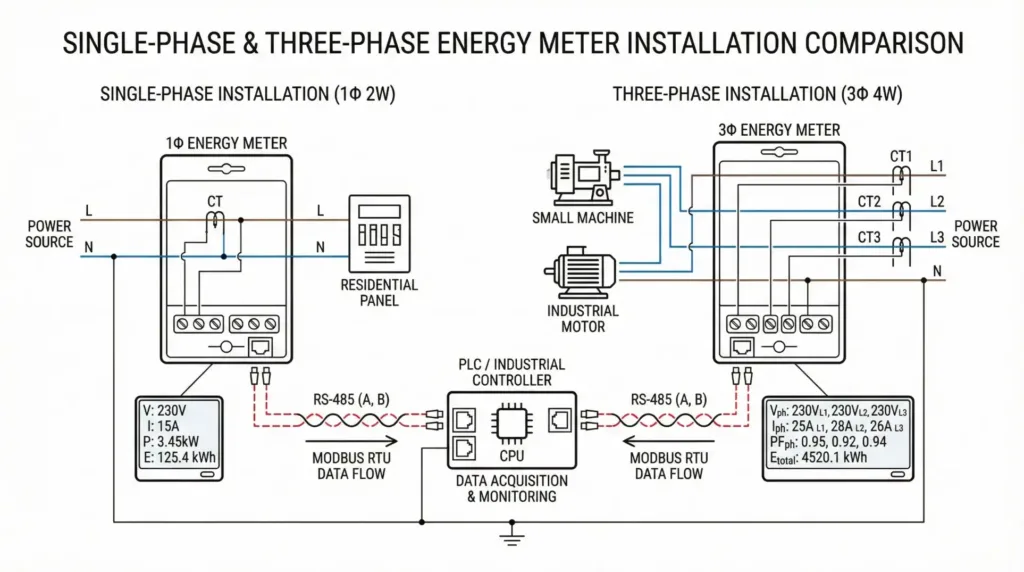

01. Energy Meters (Single-Phase, Three-Phase)

Digital energy meters form the foundation of any monitoring system. Single-phase meters track consumption for lighting, outlets, and small equipment. In contrast, three-phase meters monitor heavy machinery, HVAC systems, and primary facility feeders that typically operate at 230/400V.

Modern Modbus-enabled meters communicate digitally rather than requiring manual readings. They continuously measure critical parameters including:

- Active power (kW) and reactive power (kVAR)

- Power factor and frequency

- Voltage and current per phase

- Total energy consumption (kWh)

- Harmonics and power quality metrics

Selecting meters with Modbus RTU capability ensures seamless integration into industrial IoT energy monitoring architectures. Up to 32 meters can connect on a single RS-485 bus, significantly reducing wiring complexity.

02. Communication Protocols (Modbus RTU/TCP)

Modbus energy meter monitoring relies on proven industrial communication protocols. Modbus RTU operates over RS-485 networks using binary data transmission for reliable long-distance communication. This approach supports multiple meters on a single two-wire bus extending up to 1200 meters.

RS-485 networks use differential signaling, providing excellent noise immunity in electrically harsh industrial environments. The protocol follows master-slave architecture where edge controllers poll meters for current readings at configured intervals.

Modbus TCP, meanwhile, operates over standard Ethernet networks. It suits facilities with existing network infrastructure and enables higher data rates. Both protocols provide access to the same meter registers and parameters.

Edge Controller (NORVI X)

Edge controllers serve as the intelligent bridge between field devices and enterprise systems. The NORVI X modular industrial IoT controller excels in this role through its ESP32-S3 based design and comprehensive connectivity options.

Unlike basic PLCs, NORVI X combines ESP32-based CPU for WiFi, Bluetooth, and optional cellular connectivity with scalable I/O support. The controller handles Modbus polling, local data processing, protocol conversion, and cloud publishing without requiring separate gateways or converters.

The touchscreen display provides immediate system status visibility without external monitors. Therefore, commissioning and troubleshooting become significantly simpler compared to headless controllers.

SCADA, Cloud, and Dashboards

The application layer transforms raw meter data into actionable business intelligence. Local SCADA systems provide real-time monitoring for control room operators. Simultaneously, cloud platforms enable remote access, advanced analytics, and mobile notifications for energy managers.

Modern cloud-based energy dashboards deliver:

- Real-time power consumption visualization across facilities

- Historical trend analysis and custom reporting

- Automated alerts for threshold violations

- Integration with ERP and building management systems

- Mobile access for remote monitoring

Why Use NORVI X for Energy Meter Monitoring

Selecting the appropriate edge controller significantly impacts system performance, reliability, and total cost of ownership. NORVI X offers distinct advantages for energy meter monitoring using IoT applications.

Modular Industrial IoT Controller Architecture

NORVI X features scalable architecture that supports expansion from basic I/O to complex systems with up to 200 I/O points. The base CPU module handles core processing and communication functions. Subsequently, plug-and-play expansion modules add digital inputs, analog inputs, relay outputs, or additional communication interfaces as requirements grow.

This modularity proves particularly valuable when monitoring needs expand beyond initial project scope. Adding more RS-485 ports or I/O channels simply requires installing expansion modules rather than replacing entire systems. Consequently, total cost of ownership remains lower throughout the system lifecycle.

The DIN-rail mounting design integrates seamlessly into standard industrial control panels. Installation follows familiar practices used with traditional PLCs, minimizing training requirements for electrical contractors and system integrators.

Native RS-485 and Ethernet Support for Energy Monitoring

Most energy monitoring applications require both local industrial connectivity and network communication. NORVI X features native RS-485 Modbus connectivity that integrates seamlessly with legacy industrial equipment without external converters or adapters.

The controller supports up to 32 Modbus devices per RS-485 port through proper addressing and termination. Multiple expansion modules enable connecting additional RS-485 buses, allowing logical segregation of facility areas, voltage levels, or equipment types.

Simultaneously, built-in Ethernet connectivity enables SCADA integration using Modbus TCP or OPC UA protocols. WiFi capability provides flexible deployment options, while optional 4G LTE enables monitoring at remote facilities lacking network infrastructure.

This native multi-protocol connectivity eliminates the gateway proliferation common in traditional architectures. One controller handles all communication requirements from field devices to enterprise systems.

Edge Computing and Local Data Processing

Edge-based processing delivers critical advantages over cloud-dependent architectures. NORVI X performs local calculations including energy totalization, demand period analysis, power factor correction, and alarm condition checking. Therefore, the system maintains full monitoring functionality even during network outages.

The ESP32-S3 dual-core processor provides sufficient computational power for complex edge analytics. Local algorithms can identify anomalies, predict equipment failures based on power patterns, and trigger automated responses like load shedding.

Local non-volatile data logging ensures no readings are lost when connectivity temporarily fails. Once communication restores, the controller automatically synchronizes buffered data to cloud platforms. This edge-based energy monitoring approach guarantees data integrity and system reliability critical for industrial applications.

Developer-Friendly Programming and Customization

Unlike proprietary PLC platforms requiring expensive software licenses, NORVI X supports ESP32 development platforms including Arduino IDE, ESP-IDF, and MicroPython, allowing custom PLC-style logic, cloud connectivity (MQTT, HTTP), OTA updates, and edge processing.

This open development approach benefits both system integrators and OEMs. Engineers can leverage extensive ESP32 community resources, libraries, and example code. Custom energy monitoring algorithms, specialized protocols, or unique analytics can be implemented without vendor restrictions.

Over-the-air firmware updates enable remote system improvements and bug fixes. This capability reduces maintenance costs significantly, especially for geographically distributed installations.

System Architecture – Energy Meter to Dashboard

Understanding complete system architecture enables engineers to design robust, scalable monitoring solutions. Let’s examine each architectural layer and how they interconnect.

Field Layer: Energy Meters and Sensors

The field layer consists of digital energy meters installed at strategic monitoring points throughout the facility. Typical installation points include:

- Main incoming feeders for total facility consumption

- Individual production line or department panels

- Major equipment circuits (compressors, chillers, furnaces, injection molding machines)

- Building sub-panels for accurate cost allocation

- Critical loads requiring guaranteed power quality

RS-485 energy meters connect via daisy-chain topology using twisted-pair shielded cable. Each meter receives a unique Modbus address (1-247), enabling the controller to poll specific devices. Proper installation practices include 120-ohm termination resistors at both ends of the RS-485 bus and maintaining proper cable routing away from high-voltage power cables.

Cable selection matters significantly in industrial environments. Quality twisted-pair shielded cable ensures reliable communication despite electrical noise from VFDs, welders, and other interference sources. Cable runs can extend up to 1200 meters at standard baud rates (9600-19200 bps).

Control Layer: NORVI X as Edge Controller

NORVI X operates at the control layer, serving multiple critical functions simultaneously. First, it continuously polls connected energy meters at configurable intervals. Polling frequency depends on application requirements – critical loads might need 1-5 second updates while general monitoring suffices with 15-60 second intervals.

The controller validates received Modbus data and performs immediate calculations including:

- Rolling demand periods (typically 15-minute averages)

- Power factor and reactive power analysis

- Cost calculations based on utility rate schedules

- Efficiency metrics (energy per production unit)

- Alarm condition evaluation

Local storage in non-volatile memory protects against data loss during power interruptions. The touchscreen display shows real-time system status, active alarms, and key performance indicators without requiring external visualization tools.

Additionally, the controller can trigger local outputs based on configurable conditions. For instance, relay outputs can implement automated load shedding when approaching demand limits, or activate visual/audible alarms during abnormal conditions.

Network Layer: Local and Cloud Connectivity

The network layer enables data distribution across the organization. Locally, NORVI X connects to facility Ethernet networks using standard industrial protocols. SCADA energy monitoring architecture integration occurs through Modbus TCP, OPC UA, or custom TCP/IP protocols without proprietary gateways.

For cloud connectivity, the controller supports multiple modern IoT protocols:

- MQTT for lightweight publish-subscribe messaging to brokers like AWS IoT or Azure IoT Hub

- HTTPS REST APIs for direct platform integration with custom dashboards

- WebSockets for real-time bidirectional communication

- CoAP for constrained network environments

Optional 4G LTE cellular connectivity enables monitoring at remote sites lacking fixed network infrastructure. This proves particularly valuable for distributed manufacturing operations, remote substations, or temporary installations.

Secure VPN connectivity protects data transmission across public networks. Furthermore, local edge processing means cloud connectivity enhances rather than enables the system – monitoring continues uninterrupted even when internet connections fail.

Application Layer: Dashboards and Analytics

The application layer presents energy data through intuitive interfaces matched to user roles. Local operator stations display real-time consumption, active alarms, and operational metrics. Plant engineers access detailed performance analysis and troubleshooting tools.

Energy managers utilize web-based dashboards providing facility-wide visibility and historical trend analysis. These platforms process logged data to identify optimization opportunities, benchmark performance across facilities, and generate compliance reports.

Industrial energy analytics platforms apply machine learning algorithms to detect anomalies indicating equipment degradation before failures occur. Predictive models forecast future consumption based on production schedules, weather data, and historical patterns.

Modern platforms also enable mobile access through responsive web interfaces or dedicated apps. Energy managers can monitor facilities remotely, receive threshold notifications instantly, and investigate issues from anywhere.

Data Flow and Communication Architecture

Effective power consumption monitoring systems require efficient data flow from meters through processing to presentation. Understanding this flow enables optimal system configuration.

Modbus Polling and Data Acquisition

NORVI X initiates real-time energy data acquisition by systematically polling configured Modbus registers. For each meter, the controller sends read requests for specific parameters including voltage, current, power, energy, and power factor. Meters respond with current register values according to their configured address.

The controller manages polling schedules to balance data freshness against communication bandwidth. Sophisticated implementations use adaptive polling – increasing frequency during active production periods while reducing it during idle times to minimize bus traffic.

Multiple simultaneous Modbus conversations occur across different expansion ports efficiently. The ESP32-S3 dual-core architecture handles communication on one core while processing and analytics run on the other, ensuring responsive system performance.

Error handling includes automatic retry logic for failed communications and alerting when meters become unresponsive. This proactive approach enables maintenance teams to address communication issues before they impact monitoring accuracy.

Local Processing and Data Logging

Upon receiving meter responses, NORVI X performs immediate edge processing. The controller calculates derived values essential for energy management:

- Rolling demand periods with configurable intervals (5, 10, 15, 30 minutes)

- Power factor correction requirements and penalty calculations

- Real-time cost calculations based on complex utility rate schedules (time-of-use, demand charges)

- Efficiency metrics correlating energy consumption with production output

- Cumulative energy totals by shift, day, week, or month

All processed data writes to local non-volatile storage with configurable retention periods. Standard configurations retain high-resolution data (1-5 second intervals) for 7-30 days while maintaining hourly or daily summaries indefinitely. This edge controller for energy monitoring approach ensures complete historical records for audits and analysis regardless of network availability.

Local logging proves invaluable during network outages or cloud platform maintenance. The system continues collecting data seamlessly, automatically synchronizing to cloud platforms once connectivity restores.

Cloud and SCADA Data Publishing

Processed data publishes to configured destinations based on intelligent prioritization rules. Critical alarms transmit immediately with guaranteed delivery, while routine readings may batch for efficient bandwidth usage. This approach optimizes communication costs, particularly important for cellular-connected installations.

Data formatting adapts automatically to destination requirements. Local SCADA systems might receive straightforward Modbus TCP register mappings, while cloud platforms receive structured JSON payloads with metadata enrichment including timestamps, device IDs, and quality indicators.

The controller manages connection recovery automatically. During outages, data queues locally. Upon reconnection, the system verifies the last successfully transmitted timestamp and resumes from that point, ensuring no data loss. This robust handling distinguishes industrial-grade solutions from consumer IoT devices.

Scalability and Multi-Meter Deployment

Industrial facilities rarely maintain static monitoring requirements. Systems must scale economically as operations expand, and monitoring needs evolve.

Monitoring Multiple Panels and Feeders

Comprehensive facility monitoring tracks energy at hierarchical levels. A typical medium-sized manufacturing facility might implement:

- 1 main incoming feeder meter for total facility consumption

- 5-10 department, building, or production line sub-panel meters

- 20-50 individual equipment or machine circuit meters

- 10-20 HVAC and facility systems meters

NORVI X handles this hierarchy through its scalable architecture supporting up to 200 I/O points. Each RS-485 expansion module supports up to 32 meters, and multiple modules connect to the same controller through the internal expansion bus.

The controller automatically manages polling across all connected meters while maintaining consistent update rates. Hierarchical data aggregation occurs at the edge – department totals calculate from subordinate machine meters, facility totals aggregate from department meters. This reduces cloud communication bandwidth while providing real-time summaries.

Distributed vs Centralized Architectures

System architecture depends on facility size, geographical distribution, and communication infrastructure. Centralized architectures use a single controller location with extended RS-485 networks reaching distributed meters. This approach minimizes controller costs but faces distance and noise limitations.

Distributed architectures deploy multiple NORVI X controllers across facility areas or buildings. Each controller monitors its local meters and publishes data to centralized platforms. This approach offers significant benefits:

- Improved reliability – local failures don’t affect the entire system

- Easier cable routing in large or multi-building facilities

- Reduced noise susceptibility with shorter RS-485 runs

- Flexible expansion by adding controllers rather than extending networks

Hybrid approaches combine strategies, using local controllers for remote buildings while centralizing monitoring of adjacent areas. The optimal architecture balances initial costs against long-term maintainability and reliability requirements.

Expanding Systems Using Modular I/O

As monitoring requirements grow, NORVI X’s modular design enables seamless expansion. Adding more RS-485 ports accommodates additional meter circuits. Analog input modules integrate temperature, pressure, humidity, or flow sensors for comprehensive efficiency analysis correlating energy with environmental conditions.

Digital input modules connect production counters, run-status signals, or alarm contacts enabling correlation between energy consumption and operational context. For instance, identifying machines drawing power during confirmed non-production periods.

Digital and relay output modules enable advanced automation functions. When demand approaches limits, the controller can automatically sequence non-critical loads offline through relay outputs. Similarly, outputs can control external alarm indicators, connect to building management systems, or trigger HVAC setbacks during peak periods.

This expansion occurs through simple plug-and-play module installation without programming complex expansion card configurations. The controller automatically discovers new modules and makes their I/O available for programming.

Use Cases for Energy Monitoring with NORVI X

Real-world applications demonstrate the versatility and value of NORVI X-based monitoring systems across diverse industrial scenarios.

Factory Energy Optimization

Manufacturing facilities use smart factory energy optimization to identify waste and improvement opportunities. By correlating production data with energy consumption, engineers pinpoint inefficient operations that escape casual observation.

One textile manufacturer implemented NORVI X monitoring across 50 production machines and facility systems. Analysis revealed machines drawing full power during 15-minute break periods, compressed air systems with significant leakage, and HVAC systems overcooling unoccupied areas during night shifts. Implementing targeted improvements reduced overall consumption by 18% within six months, saving $150,000 annually.

The system enabled production scheduling optimization around time-of-use rates. Energy-intensive processes shifted to off-peak periods where practical, reducing demand charges substantially.

Peak Demand Monitoring and Control

Utility demand charges represent 30-50% of industrial electricity costs in many regions. Therefore, monitoring and controlling peak demand becomes crucial for cost management. NORVI X tracks rolling demand periods continuously, comparing current demand against monthly targets.

Advanced implementations provide early warning through the touchscreen display and mobile notifications before exceeding thresholds. When approaching limits, the system automatically sequences non-critical loads offline temporarily – production continues while auxiliary equipment like compressors, chillers, or dust collectors cycle strategically.

One automotive parts manufacturer reduced monthly demand charges by 35% using automated load shedding. The NORVI X system coordinated 12 different loads across the facility, maintaining production throughput while limiting peak demand.

Energy Audits and Compliance

ISO 50001 energy management certification requires documented monitoring systems with accurate historical data. NORVI X provides the data logging and reporting capabilities auditors require. The system automatically generates consumption reports, trend analysis, efficiency metrics, and compliance documentation.

Furthermore, many jurisdictions mandate energy reporting for facilities exceeding certain consumption thresholds. Automated monitoring eliminates manual data collection errors while ensuring complete, auditable records. Export functions provide data in formats required by regulatory agencies.

The local data logging capability ensures no gaps in monitoring records even during network outages – a critical requirement for compliance applications where data integrity is paramount.

OEM Energy Monitoring Solutions

Machine builders increasingly differentiate their products by integrating energy monitoring capabilities. End customers demand visibility into individual machine consumption for cost allocation and efficiency benchmarking. NORVI X provides an ideal platform for OEM integration.

The compact DIN-rail form factor fits easily within machine control panels. Pre-configured programming templates accelerate development, while flexible ESP32 programming enables customization for specific machine types. OEMs can brand the touchscreen interface and develop custom dashboards matching their corporate identity.

One packaging equipment manufacturer embedded NORVI X in their production line controllers. Customers receive real-time visibility into energy consumption per package produced, enabling data-driven decisions about production speed versus energy cost optimization. This differentiation helped the OEM win contracts over competitors lacking these capabilities.

Frequently Asked Questions

An energy meter monitoring system continuously collects power consumption data from digital energy meters, processes it through edge controllers like NORVI X, and presents actionable insights through dashboards. This enables real-time visibility, historical analysis, and optimization of industrial energy usage.

NORVI X connects to energy meters using RS-485 communication with Modbus RTU protocol. Multiple meters (up to 32 per port) connect through daisy-chain wiring to expansion modules. Each meter receives a unique address enabling selective polling and data collection.

Yes, NORVI X performs all core functions locally including meter polling, data logging, calculations, and alarm generation. Cloud connectivity enhances capabilities with remote access and advanced analytics but isn’t required for basic operation. The system continues monitoring seamlessly during network outages.

Each RS-485 expansion port supports up to 32 Modbus devices. Multiple expansion modules enable monitoring hundreds of meters from one controller. However, distributed architectures using multiple controllers often prove more practical for very large installations with over 100 monitoring points.

NORVI X supports MQTT, HTTPS REST APIs, Modbus TCP, OPC UA, WebSockets, and custom TCP/IP protocols. This flexibility enables integration with virtually any cloud platform, SCADA system, or custom dashboard application. Optional 4G LTE provides connectivity where network infrastructure is unavailable.

Yes, NORVI X integrates seamlessly with existing SCADA platforms through standard industrial protocols including Modbus TCP and OPC UA. The controller acts as a Modbus slave or OPC UA server, making meter data available to SCADA systems without proprietary gateways or converters.

Basic programming knowledge helps, but extensive example code and libraries simplify development. NORVI X supports Arduino IDE with C/C++, ESP-IDF framework, and MicroPython. The extensive ESP32 community provides resources and support. Pre-configured templates accelerate common energy monitoring applications.

Conclusion

Effective industrial energy management begins with comprehensive, reliable monitoring. Understanding complete system architecture – from field-level meters through intelligent edge controllers to cloud analytics – enables engineers to design solutions delivering measurable results.

Benefits of Edge-Based Energy Monitoring

Edge-based energy monitoring delivers distinct advantages over cloud-dependent architectures. Local processing ensures system reliability regardless of network conditions. Real-time edge analytics enable immediate response to anomalies without cloud latency or dependency.

Distributing intelligence across edge devices reduces bandwidth requirements and cloud storage costs significantly. Edge systems also address data privacy and security concerns by keeping sensitive operational data on-premises while publishing only aggregated metrics externally.

Furthermore, edge processing enables advanced local automation like automated load shedding during peak demand periods. These critical functions cannot tolerate cloud communication delays or outages.

Why NORVI X Perfectly Fits Industrial Energy Monitoring

NORVI X combines industrial-grade reliability with modern IoT connectivity and flexibility. Its native RS-485 Modbus connectivity integrates seamlessly with legacy industrial equipment while simultaneously supporting WiFi, Ethernet, and optional cellular connectivity for cloud integration.

The modular expansion architecture accommodates growing requirements without system replacement. Starting with basic monitoring, facilities can progressively expand capabilities by adding modules as budgets allow and needs evolve.

For system integrators, NORVI X accelerates project delivery through simplified wiring, intuitive programming, and comprehensive example code. For end users, it delivers reliable, scalable monitoring that reduces energy costs while improving operational visibility and control.

Whether retrofitting existing facilities or designing new installations, NORVI X provides the foundation for effective industrial IoT energy monitoring. The combination of proven ESP32 technology, industrial-grade hardware design, and open programming flexibility makes it an ideal choice for demanding industrial applications.

Ready to implement industrial energy monitoring in your facility?

Contact our engineering team for a customized architecture consultation and discover how NORVI X can transform your energy management capabilities. Start optimizing your energy consumption today with proven edge-based monitoring technology.

Subscribe to our newsletter for monthly insights on industrial automation, energy management strategies, and NORVI Controllers updates.