NORVI Controllers as Modbus Controller: Revolutionizing Industrial Automation

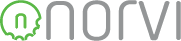

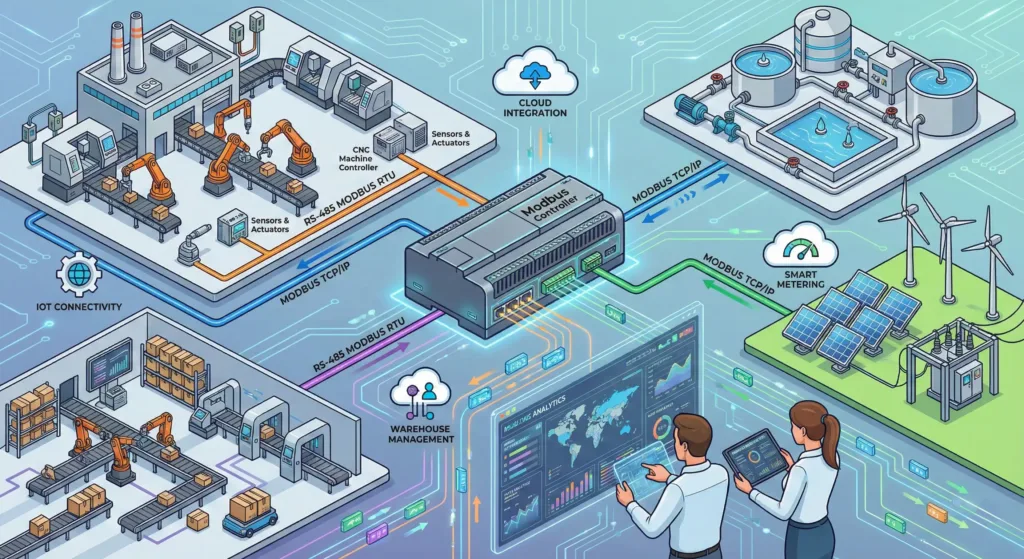

Industrial automation systems increasingly rely on robust communication protocols to ensure seamless data exchange between devices. Among these protocols, NORVI controllers Modbus implementation stands out as a particularly effective solution for modern industrial applications. These versatile controllers combine the reliability of Modbus protocol with advanced ESP32-based technology, creating powerful automation platforms that meet today’s demanding industrial requirements.

Furthermore, the integration of NORVI controllers with Modbus protocol offers manufacturers and system integrators a cost-effective pathway to modernize their automation infrastructure. Consequently, understanding the capabilities and implementation strategies of these controllers becomes essential for professionals seeking to optimize their industrial communication networks.

What is a Modbus Controller and Why It’s Crucial in Industrial Automation

In the fast-evolving world of industrial automation, communication between devices is critical. One of the most widely adopted standards for industrial communication is Modbus. But what exactly is a Modbus controller, and why should engineers and system integrators care about it? Let’s explore.

Understanding Modbus: The Backbone of Industrial Communication

Modbus is a communication protocol developed in 1979 by Modicon (now Schneider Electric). It was designed to allow electronic devices, like sensors, meters, and PLCs, to exchange data reliably. What makes Modbus exceptional is its simplicity, openness, and interoperability, which has made it a global standard in industrial automation.

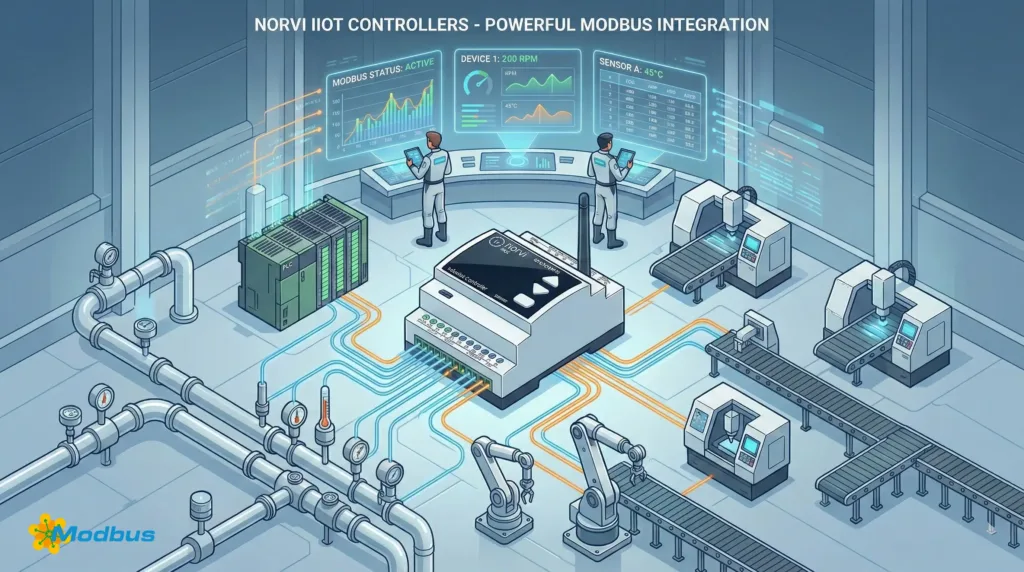

Modbus operates at the application layer of the OSI model and can run over various physical networks such as:

- RS-232 and RS-485 serial lines (RTU or ASCII modes)

- Ethernet (TCP/IP)

This flexibility allows Modbus to connect both legacy and modern devices seamlessly.

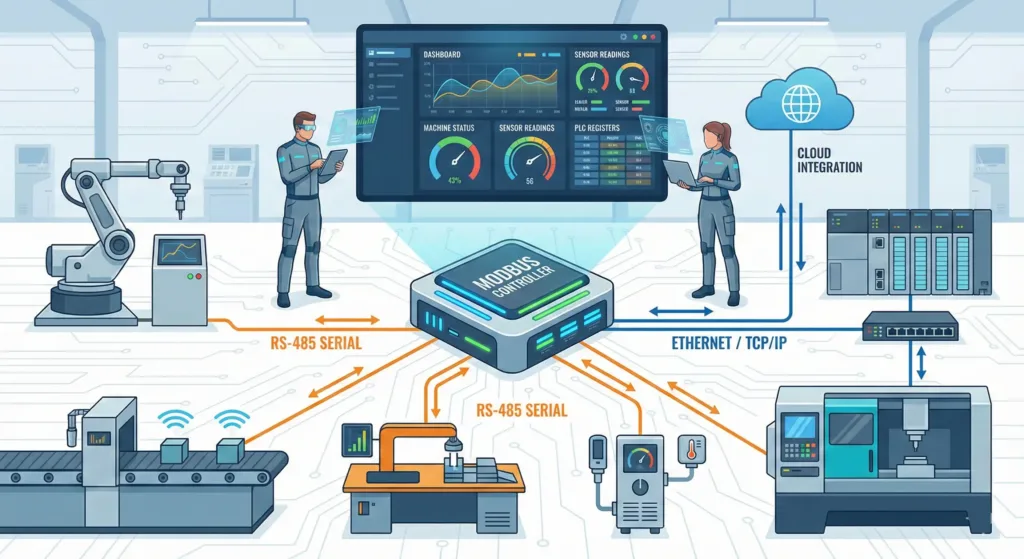

How Modbus Works

Modbus follows a client-server architecture, previously known as master-slave. Here’s the basic operation:

- The master (controller) sends a request to a specific slave device.

- The request contains a function code, target address, and data.

- The slave responds with the requested data or an acknowledgment of action.

This process allows a Modbus controller to monitor and control multiple devices from a single central point, making automation more efficient.

What is a Modbus Controller?

A Modbus controller is essentially any device that can initiate communication with other Modbus-enabled devices. Typically, it can be:

- PLC (Programmable Logic Controller): The most common Modbus controller used in factories and industrial plants.

- PAC (Programmable Automation Controller): A more flexible option for complex automation tasks.

- SCADA / HMI systems: Supervisory devices that collect and visualize data from multiple Modbus slaves.

In simple terms, a Modbus controller is the brain of a Modbus network – coordinating data collection, processing, and control actions.

NORVI Controllers as a Modbus Controller

Advanced Hardware Architecture

NORVI Controllers feature sophisticated hardware designed specifically for industrial environments. Almost all the NORVI controller has RS-485 connectivity standard or as an option, ensuring seamless integration with existing Modbus networks. Moreover, the controllers support multiple communication protocols, with Modbus RTU and Profibus are the widely used protocols among them.

The ESP32-based architecture provides several advantages:

- Robust Processing Power: High-performance microcontroller capable of handling complex Modbus operations

- Multiple Communication Interfaces: Built-in Wi-Fi, Ethernet, and RS485 connectivity options

- Industrial-Grade Design: Temperature and voltage tolerance suitable for harsh industrial environments

- Expandable I/O Configuration: Flexible input/output options for diverse application requirements

RS485 Connectivity Excellence

The foundation of effective Modbus communication lies in reliable RS485 connectivity. NORVI controllers excel in this area by providing:

- Standard RS485 Terminals: Dedicated terminals for multidrop device connections

- Flow Control Management: Automatic flow control pin configuration for optimal data transmission

- Noise Immunity: Industrial-grade RS485 transceivers that resist electromagnetic interference

- Long-Distance Communication: Support for extended cable runs up to 1200 meters

Additionally, the controllers feature automatic baud rate detection and error correction mechanisms, ensuring stable communication even in challenging industrial environments.

NORVI IIoT | ESP32 Industrial Modbus Controller

Built-in OLED Display | Digital Input / Relay / Transistor / PWM | 0 – 10V / 4 20mA | micro-SD Card support | DS3231 RTC

Buy NowComprehensive Modbus Implementation Modes

Master Controller Configuration

NORVI-IIOT-AE02 device acting as a MODBUS master demonstrates the versatility of these controllers in network topologies. When configured as Modbus masters, NORVI controllers can:

- Poll Multiple Slaves: Systematically collect data from numerous field devices

- Implement Custom Polling Strategies: Optimize data collection based on application priorities

- Handle Exception Responses: Gracefully manage communication errors and device failures

- Maintain Network Diagnostics: Monitor network health and device status continuously

The master configuration particularly benefits manufacturing facilities requiring centralized data collection from distributed sensors and actuators.

NORVI-IIOT-AE02-V

Price: $98.23 USD

8x Sink/Source Digital Inputs | 6x 0-10V Analog Inputs | 2x Open collector Transistor | RS-485 | 0.96′ OLED Display

Buy Now

NORVI-IIOT-AE02-I

Price: $115.83 USD

8x Sink/Source Digital Inputs| 6x 4-20mA Analog Inputs | 2x Open collector Transistor | RS-485 | 0.96′ OLED Display

Buy NowSlave Device Functionality

Operating as Modbus slaves, NORVI controllers provide excellent gateway functionality. This program sets up a NORVI-IIOT-AE02 device acting as a MODBUS slave, enabling seamless integration with existing SCADA systems and higher-level controllers.

Key slave mode capabilities include:

- Register Mapping: Flexible mapping of physical I/O to Modbus registers

- Real-Time Response: Fast response times to master requests

- Data Buffering: Intelligent data buffering for consistent communication

- Protocol Translation: Convert between different industrial protocols

Real-World Applications and Use Cases

Manufacturing Process Control

In manufacturing environments, NORVI controllers Modbus implementation enables comprehensive process monitoring and control. For instance, automotive assembly lines utilize these controllers to:

- Monitor conveyor speeds and positions through encoder inputs

- Control pneumatic actuators for part positioning

- Interface with barcode scanners for product tracking

- Communicate with quality control stations

The reliability of Modbus protocol combined with NORVI’s industrial design ensures consistent operation in 24/7 manufacturing environments.

Building Automation Systems

Smart buildings increasingly rely on Modbus networks for HVAC control, lighting management, and energy monitoring. NORVI Controllers serve as intelligent gateways that:

- Collect data from temperature and humidity sensors

- Control variable frequency drives for HVAC systems

- Interface with energy meters for consumption monitoring

- Provide web-based monitoring interfaces through integrated Wi-Fi

Water Treatment and Distribution

Municipal water systems benefit significantly from NORVI controllers’ Modbus capabilities. These applications typically involve:

- Remote Monitoring: Collecting data from distributed pump stations and treatment facilities

- Alarm Management: Immediate notification of system failures or parameter deviations

- Flow Control: Precise control of valve positions and pump speeds

- Data Logging: Historical data collection for regulatory compliance

Implementation Best Practices and Technical Considerations

Network Configuration Guidelines

Successful NORVI controllers Modbus implementation requires careful attention to network configuration details. Essential considerations include:

- Addressing Scheme: Assign unique device addresses (1-247 for RTU networks)

- Baud Rate Selection: Choose appropriate baud rates (typically 9600-115200 bps)

- Termination Resistors: Install 120-ohm termination resistors at network ends

- Cable Specifications: Use proper twisted-pair cables with appropriate impedance

Programming and Development

Utilize existing libraries like “ModbusMaster” or “Modbus RTU” for Arduino/ESP-IDF to handle MODBUS communication. This approach streamlines development while ensuring protocol compliance.

Recommended development practices include:

- Error Handling: Implement comprehensive error detection and recovery mechanisms

- Timeout Management: Configure appropriate timeout values for network conditions

- Data Validation: Verify data integrity using CRC and range checking

- Documentation: Maintain detailed register maps and configuration documentation

Find GitHub resource file for: Modbus RTU Master, Modbus RTU Slave, Modbus TCP Master

Troubleshooting Common Issues

Common implementation challenges and solutions:

- Communication Timeouts: Adjust timeout parameters and verify network integrity

- Data Corruption: Check cable quality and eliminate electromagnetic interference sources

- Device Conflicts: Verify unique addressing and eliminate duplicate device IDs

- Performance Issues: Optimize polling intervals and implement efficient data structures

Integration with Modern IoT Platforms

Cloud Connectivity

Norvi controllers bridge traditional Modbus networks with modern cloud platforms through:

- MQTT Protocol Support: Real-time data streaming to cloud services

- REST API Integration: HTTP-based communication with enterprise systems

- Edge Computing: Local data processing and intelligent filtering

- Security Features: Encrypted communication and authentication mechanisms

Industry 4.0 Compatibility

The controllers support Industry 4.0 initiatives by providing:

- Predictive Maintenance: Continuous monitoring and trend analysis

- Digital Twin Integration: Real-time synchronization with digital models

- Advanced Analytics: Edge-based data processing and anomaly detection

- Flexible Connectivity: Multiple protocol support for diverse equipment

Future Developments and Trends

The evolution of Norvi controllers Modbus technology continues with emerging trends including:

- Enhanced Cybersecurity: Advanced encryption and authentication protocols

- AI Integration: Machine learning capabilities for intelligent automation

- 5G Connectivity: Ultra-low latency communication for critical applications

- Standardization Efforts: Improved interoperability through industry standards

Conclusion

NORVI Controllers represent a significant advancement in Modbus controller technology, offering industrial facilities a powerful combination of reliability, flexibility, and modern connectivity options. Through their comprehensive support for both master and slave operations, these controllers enable seamless integration of legacy Modbus networks with contemporary IoT infrastructure.

The technical excellence of NORVI Controllers Modbus implementation, combined with their cost-effective pricing and extensive support resources, makes them an ideal choice for organizations seeking to modernize their industrial automation systems. Whether you’re upgrading existing facilities or designing new automation networks, these controllers provide the foundation for robust, scalable, and future-ready industrial communication systems.

Ready to transform your industrial automation with Norvi controllers? Explore our comprehensive range of Modbus-compatible controllers and discover how they can enhance your operational efficiency and connectivity.

Ready to Build Your Custom IoT Solution?

Partner with IoT experts who understand your industry challenges. From hardware design to cloud integration, we deliver tailored solutions that drive measurable ROI.

Start Your Project TodayShare this with others:

Got Questions?

For any technical assistance or inquiries, please contact our technical team at support@norvi.io. We are happy to assist you.