Modular Conveyor Control System Using NORVI X: The Complete Guide

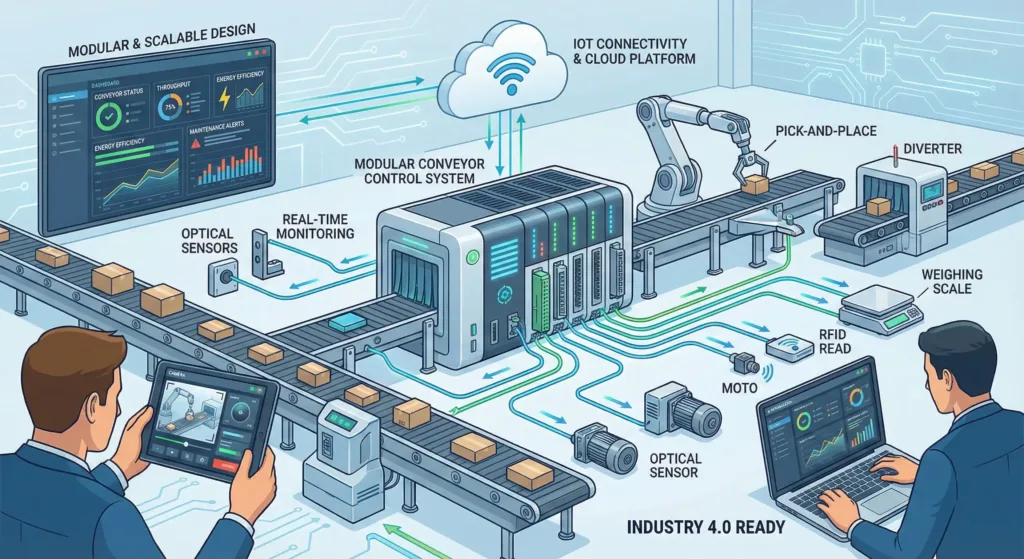

Modern manufacturing demands flexible, scalable conveyor automation solutions. Traditional conveyor systems often lock you into rigid configurations that are expensive to modify. However, a Modular Conveyor Control System changes everything. In this comprehensive guide, we’ll explore how NORVI X, a powerful modular industrial controller, transforms conveyor automation with its innovative design that serves as an ideal PLC alternative for modern factories.

Introduction to Modular Conveyor Control Systems

Why Modularity Matters in Modern Industrial Automation

Manufacturing environments constantly evolve. Production lines expand, product types change, and throughput requirements shift. Consequently, your control system must adapt without requiring complete overhauls.

A modular conveyor control system offers unprecedented flexibility. Instead of replacing entire control panels, you simply add or remove conveyor control modules as needed. This approach to conveyor automation saves both time and money while reducing downtime. Moreover, modular industrial controllers simplify troubleshooting, when a component fails, you swap out a single module rather than diagnosing complex hardwired systems.

Common Limitations of Traditional Conveyor Control Setups

Traditional conveyor control systems create several headaches for plant managers. Fixed I/O configurations force you to oversize your initial investment. You pay for capacity you might never use, just in case future expansion becomes necessary.

Extensive hardwiring makes modifications labor-intensive and error-prone. Every change requires electricians to trace wires, modify panels, and test connections extensively. Additionally, limited communication options isolate your conveyors from modern Industry 4.0 initiatives. Older systems lack the connectivity needed for industrial IoT conveyor systems that enable real-time monitoring and data analytics.

Vendor lock-in restricts your choices when expanding or upgrading. Proprietary systems often require expensive components from a single manufacturer. These limitations directly impact your bottom line through higher costs, longer downtimes, and missed opportunities for optimization.

What Is NORVI X?

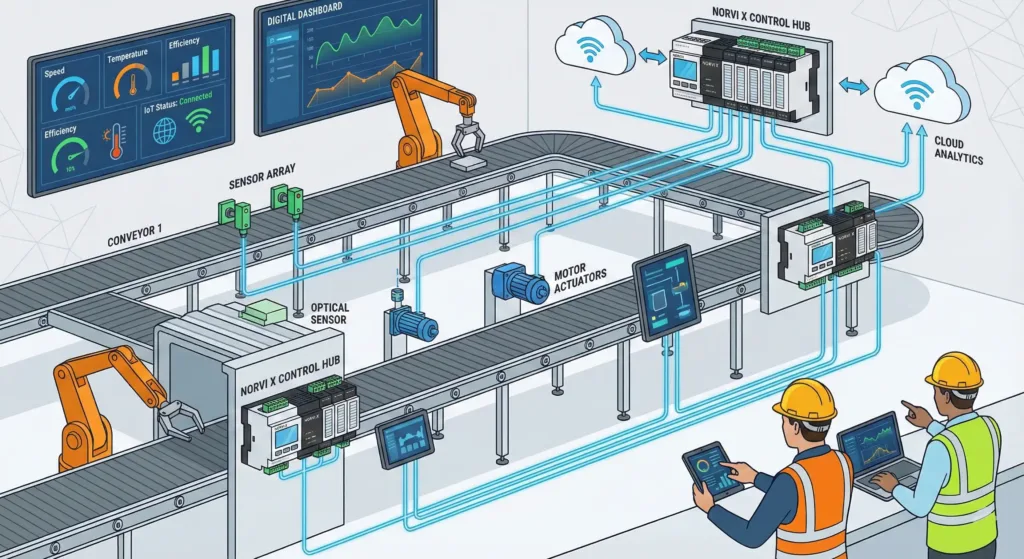

Overview of the Modular Industrial IoT Controller

NORVI X represents the next generation of industrial control hardware and stands out as a superior PLC alternative. Built around the powerful ESP32-S3 microcontroller, it combines traditional PLC functionality with modern IoT capabilities. The system features a central CPU module that handles all processing tasks. You then expand capabilities by connecting plug-and-play conveyor control modules for inputs, outputs, and specialized functions.

📚 Documentation Tip: Visit the NORVI X datasheet for complete technical specifications and GPIO pin assignments.

Key Features Relevant to Conveyor Automation

NORVI X delivers several features that make it ideal for conveyor automation applications. Built-in RS-485 communication enables Modbus RTU connectivity for motor drives and sensors. This industrial-standard protocol ensures reliable communication in electrically noisy environments.

Integrated Ethernet support via W5500 PHY provides fast, stable networking. Connect multiple NORVI X units across your facility for coordinated conveyor control. The real-time clock (RTC) maintains accurate timestamps for data logging and scheduled operations.

Furthermore, the TFT touchscreen display offers local monitoring and control without additional HMI hardware. Operators can check status, adjust parameters, and acknowledge alarms directly at the controller. WiFi and Bluetooth connectivity open possibilities for wireless sensor integration and mobile monitoring.

Advantages Over PLCs and Fixed-Control Hardware

NORVI X outperforms traditional PLCs in several key areas, making it an exceptional PLC alternative for modern conveyor automation. Cost efficiency starts with the hardware itself—this modular industrial controller costs significantly less than comparable PLCs while offering superior connectivity and processing power.

Faster deployment results from simplified wiring and configuration. Expansion modules connect with standard cables rather than requiring custom panel modifications. Modern programming options include Arduino IDE and ESP-IDF frameworks. Your team can leverage extensive open-source libraries and community support rather than learning proprietary programming languages.

💡 Pro Tip: NORVI controllers are fully compatible with Arduino libraries, meaning you can use thousands of pre-tested code examples from the Arduino community.

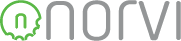

System Architecture and Setup

Hardware Configuration

Begin by mounting the NORVI X CPU module on DIN rail in your control cabinet. Ensure adequate spacing for cooling airflow and cable management. Install expansion conveyor control modules adjacent to the CPU—each module snaps onto DIN rail and connects to its neighbors with short interconnect cables.

Available expansion modules include 4, 8, or 16 digital input modules for sensors and switches, plus 4 or 8 relay output modules for motors and actuators. You can also add 4-channel analog input modules (0-10V or 4-20mA) for analog sensors and 4-channel analog output modules for VFD speed control. This flexibility makes NORVI X the ideal modular industrial controller for scalable industrial IoT conveyor systems.

⚡ Power Supply Sizing Tip: Calculate total current draw for all modules plus 30% margin.

Wiring Sensors and Motor Drivers

Connect sensors to digital input modules using shielded twisted-pair cables. Observe correct polarity for PNP and NPN sensor types. For best noise immunity, route sensor cables separately from power cables—maintain at least 12 inches separation.

Wire analog sensors to analog input modules with shielded cables. Connect shields to the module’s shield terminal, not to sensor housings, to avoid ground loops. Connect relay outputs to motor contactors and solenoids through appropriately rated circuit breakers or fuses.

🔍 Troubleshooting Tip: Digital input issues are often caused by incorrect COM terminal wiring.

Communication Setup

Configure network settings through NORVI X’s web interface. Assign static IP addresses for reliable connectivity, or use DHCP in simpler installations. Set up Modbus TCP by defining slave addresses for connected devices. NORVI X can act as a Modbus master polling VFDs and remote I/O, or as a slave responding to SCADA requests.

Configure MQTT by specifying broker addresses, topics, and quality-of-service settings. Publish sensor data at appropriate intervals, faster for critical values, slower for less important data to conserve bandwidth.

🔌 Network Design Tip: Always install 120-ohm termination resistors at both ends of the RS-485 bus.

Common Conveyor Control Functions

Start/Stop Logic and Safety

Basic start/stop control forms the foundation of every conveyor automation system. Monitor a start button input and check that all safety interlocks are satisfied, emergency stops released, guards closed, overload conditions clear. If safe conditions exist, energize the motor contactor through a relay output.

Implement run permissive logic that prevents starting under unsafe conditions. Display clear messages on the HMI explaining why starting is currently disabled. Add delayed restart after stops to allow mechanical settling and prevent rapid cycling that stresses motors and belts.

🔐 Safety Logic Pattern: Always implement a dual-channel emergency stop circuit.

Speed Control and VFD Integration

Many conveyor automation projects require variable speeds for different products or processes. Adjust motor speed via analog outputs to VFD speed reference inputs. Scale operator setpoints or automatic control calculations to the 0-10V or 4-20mA range expected by your drives.

Create speed profiles for smooth acceleration and deceleration. Gradual ramping prevents product spillage, belt slippage, and mechanical shock loads. NORVI X communicates with VFDs via Modbus for coordinated multi-motor operations.

📡 Modbus Example: Many VFDs use register 40001 for start/stop commands.

Load Detection and Jam Prevention

Preventing jams protects equipment and maintains productivity. Monitor motor current through analog inputs from VFDs or current transducers. Rising current indicates increasing load—possibly a developing jam. When current exceeds thresholds for more than 3 seconds, reduce speed or stop the belt.

Use photoelectric arrays to detect product accumulation. When products back up beyond normal levels, slow or stop upstream conveyors while downstream sections clear the backlog. Implement timeout logic for product tracking—if a product doesn’t reach the next sensor within expected times, a jam may have occurred.

💡 Preventive Tip: Log all jam events and analyze weekly for patterns.

Real-World Applications

Manufacturing Assembly Lines

Assembly operations require precise product positioning and timing. NORVI X coordinates multiple conveyors, index tables, and robotic stations seamlessly as part of an industrial IoT conveyor system. Products move between workstations on NORVI X-controlled conveyors, with sensors detecting product arrival and triggering assembly operations.

Station-to-station communication via Ethernet ensures coordination. Upstream stations don’t release products until downstream stations are ready to receive them. Quality tracking associates data with each product throughout assembly.

Warehouse and Logistics Systems

Distribution centers move thousands of parcels daily through complex conveyor networks. NORVI X manages sortation systems that route packages to hundreds of destinations based on barcode scans or RFID tags. This modular industrial controller coordinates diverters, pushers, and pop-up transfers with millisecond precision.

Merge controls combine products from multiple infeed lines onto main conveyors without collisions. Zone control divides long conveyors into sections that operate semi-independently, balancing flow throughout the facility.

Food Processing and Packaging

Food industry conveyors face unique challenges including sanitation requirements and temperature extremes. NORVI X’s sealed enclosure resists moisture and cleaning chemicals, surviving regular washdowns without corroding or failing. This makes it an excellent PLC alternative for food processing conveyor automation.

Temperature monitoring through analog inputs ensures food safety. Refrigerated conveyors maintain proper temperatures throughout processing. Weight checking via load cells verifies portion control and prevents giveaway. NORVI X triggers automatic rejection of under- or overweight products while maintaining traceability logging for HACCP compliance.

Integration With Enterprise Systems

Connecting to SCADA and MES

NORVI X connects to existing factory systems through standard protocols, making it a versatile PLC alternative. Modbus TCP enables communication with virtually all industrial SCADA packages. Configure NORVI X as a Modbus slave, then poll its registers from your existing supervisory systems.

OPC-UA provides standardized, secure communication with MES and ERP platforms. Define data structures matching your enterprise models for seamless integration. Database connectors write production data directly to SQL databases for custom reports and analytics.

Cloud Integration and Remote Monitoring

Modern conveyor automation demands visibility from anywhere. Web dashboards hosted on NORVI X provide secure remote access. Managers monitor production from offices, homes, or mobile devices without VPN complexity.

Cloud dashboards built with services like AWS QuickSight or Microsoft Power BI offer sophisticated visualization and analytics. Mobile apps connect via MQTT or REST APIs for on-the-go monitoring. Maintenance technicians receive instant notifications of alarms or abnormal conditions.

🛡️ Security Best Practice: Never expose NORVI X directly to the internet.

Cost Benefits and ROI

Reduced Installation Costs

Traditional conveyor systems require extensive point-to-point wiring from sensors and actuators to central control panels. Distributed control with multiple NORVI X nodes dramatically reduces wiring runs. Each modular industrial controller connects to nearby sensors and actuators with short cables, while controllers communicate via single network cables.

Modular expansion with conveyor control modules eliminates custom panel modifications. Simply plug in additional modules rather than hiring electricians to wire new terminals and run conduit. These factors typically reduce installation costs by 30-40% compared to traditional systems.

💰 Cost Comparison: NORVI X can reduce system cost by more than 50% compared to PLC systems.

Lower Maintenance and Downtime

Unplanned downtime costs far more than the direct expense of repairs. Faster troubleshooting through comprehensive diagnostics reduces downtime duration. Technicians identify failed components in minutes rather than hours.

Module-level replacement gets systems running quickly. Swap a defective expansion module in seconds, then diagnose the failed unit offline. Predictive maintenance prevents failures before they occur by analyzing motor current, vibration sensors, and temperature data.

These factors typically reduce maintenance costs by 20-30% while significantly improving uptime. If your conveyor generates $500/hour in value, reducing downtime from 40 to 25 hours annually saves $7,500 in lost production, plus lower maintenance labor costs.

Scalability and Futureproofing

Business needs change constantly. New products require different handling, and production volumes increase or shift to different facilities. NORVI X adapts to these changes without starting over. Add capacity by installing additional conveyor control modules or controllers with minimal programming changes.

Relocate equipment easily because modular systems disassemble and reassemble quickly. Reuse components from discontinued lines in new applications. This flexibility protects your automation investment over many years of changing requirements.

Conclusion

Summary of Benefits

A modular conveyor control system built on NORVI X delivers compelling advantages over traditional approaches. Flexibility lets you start small and expand organically as needs evolve, while cost efficiency reduces both initial investment and ongoing expenses through simplified installation and easier maintenance with conveyor control modules.

Modern connectivity bridges operational technology and information technology seamlessly. Integrate conveyors with SCADA, MES, cloud platforms, and analytics tools effortlessly using this industrial IoT conveyor system. Reliability through industrial-grade hardware and distributed control architectures keeps production running even when components fail.

Getting Started

Ready to implement NORVI X in your facility? Start by assessing your current system and documenting I/O requirements. Choose a single conveyor line for a pilot project to gain experience with the platform. Review NORVI X datasheets and wiring guides at Documentations

Order hardware for your pilot project, then develop and test your control program on a workbench before installation. Mount hardware, connect wiring, and gradually transition from your old system. Monitor performance metrics and refine your logic based on real-world operation.

🚀 Implementation Tip: Train your maintenance team early to boost success rates.

The modular conveyor control system revolution has arrived. Organizations that embrace these capabilities gain significant competitive advantages through faster response to market changes, optimized operations through data analytics, and more efficient processes than competitors using traditional approaches. As a powerful PLC alternative with advanced conveyor automation features, NORVI X represents the future of industrial control. The choice and the competitive advantage are yours.

Ready to Build Your Custom IoT Solution?

Partner with IoT experts who understand your industry challenges. From hardware design to cloud integration, we deliver tailored solutions that drive measurable ROI.

Start Your Project TodayShare this with others:

Got Questions?

For any technical assistance or inquiries, please contact our technical team at support@norvi.io. We are happy to assist you.