End-to-End IoT Product Development: From Idea to Mass Production

IoT product development is more than designing electronics; it’s about transforming ideas into scalable, reliable solutions that solve real-world challenges. At NORVI, we treat IoT product development as a complete, end-to-end journey. First, we start by understanding customer requirements, including data transfer needs, power sources, and operating environments. Then, during design and prototyping, we apply our expertise to ensure every component integrates seamlessly. Throughout this phase, we actively test and refine the system, ensuring that it performs effectively in practical conditions. By focusing on every detail from the very beginning, our IoT product development process guarantees products that are not only technically sound but also safe, practical, and installer friendly.

Next, we move into full-scale production, where our IoT product development emphasizes consistency, quality control, and traceability. By handling design and manufacturing in-house, we reduce reliance on external vendors, accelerate turnaround times, and maintain full control over the final product. Moreover, our team continuously optimizes the process, ensuring devices meet certifications and customer expectations. Ultimately, NORVI’s end-to-end IoT product development empowers innovators and enterprises to go from concept to mass-produced, reliable devices, delivering solutions that truly succeed in real-world deployment.

IoT Product Development: Understanding Customer Requirements

Every IoT project begins with a thorough deep dive into the customer’s requirements. First, this step shapes all subsequent decisions, and it also ensures that we design a product that meets the demands of real-world deployment. To achieve this, we focus on:

- Data Characteristics – How often will the device transfer data? What’s the size and criticality of that data?

- Power Source – Can the device be powered by the grid, or must it rely on batteries for years?

- Operating Environment – Will it be used indoors, outdoors, or in harsh industrial conditions?

In addition, we also evaluate the hardware integration needs:

- Sensors: Which types of sensors should you connect—analog, digital, or industrial (for example, 4–20 mA, RS-485, or Modbus)?

- Inputs & Outputs: How many I/Os are required, and what kind—relays, digital switches, analog inputs, PWM outputs, etc.?

- Indicators: LEDs, buzzers, or display screens for local status feedback.

- Installation Methods: Mounting options (DIN rail, wall mount, pole mount, etc.) that allow quick and efficient deployment at scale.

- Labelling & Identification: Proper labeling for ports, safety instructions, and device ID to ensure easy maintenance and compliance in the field.

By first clarifying these details up front, we can then design products that are not only technically sound but also practical, safe, and installer friendly. Furthermore, this approach ensures that every design decision aligns with real-world usage and customer expectations, ultimately resulting in reliable and user-centered IoT solutions.

IoT Product Development: Customer Requirement Checklist

When planning your IoT product, consider the following points to ensure a smooth development process:

- What data do you need to capture, and how often?

- How critical is the data (real-time vs. periodic reporting)?

- How are we going to power the device based on customer request (grid, battery, or hybrid)?

- In what environment will the device operate (indoor/outdoor/industrial)?

- Which sensors we need to connect to fill the right requirement (temperature, pressure, vibration, etc.)?

- What inputs and outputs will require (digital, analog, relay, communication ports)?

- What indicators (LEDs, buzzers, displays) are necessary for local feedback?

- What installation method works best (DIN rail, wall mount, pole mount, enclosure type)?

- What labelling or safety markings will require for compliance and easy identification?

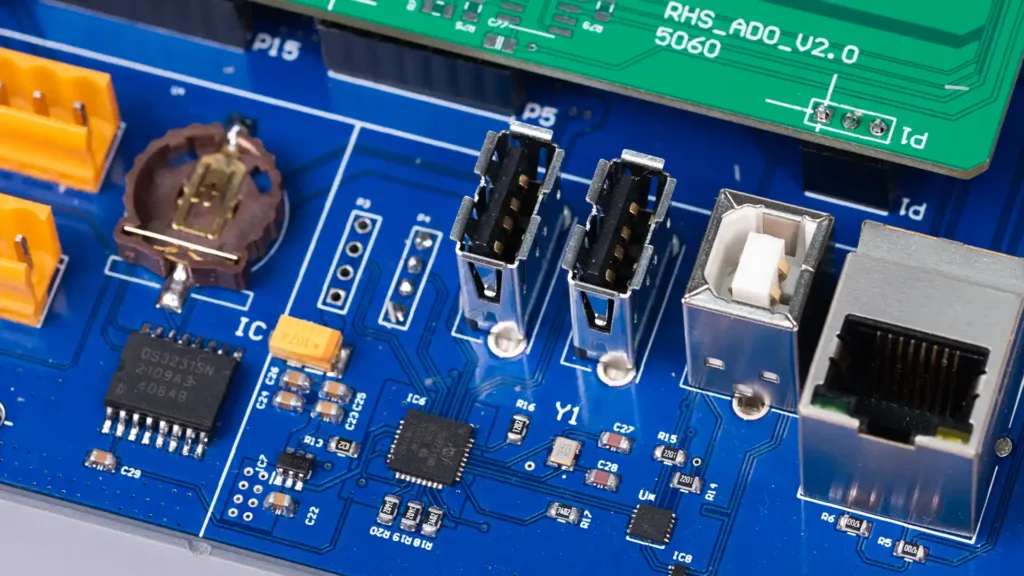

Choosing the Core Components

Once requirements are clear, we select components that ensure performance, reliability, and scalability, building a strong foundation for production-ready IoT devices.

- Microcontroller (MCU): balancing performance, memory, and power consumption.

- Sensors: selected based on accuracy, reliability, and environmental durability.

- Power Design: ensuring the device meets operational lifetimes, especially for battery-powered systems

For low-power devices, selecting the right communication method is critical. First, we evaluate the data requirements and power budget. Then, whether it’s Wi-Fi, Ethernet, Cellular, LoRaWAN, or Bluetooth, we carefully match the technology to the device’s needs. In addition, we consider factors such as range, reliability, and environmental conditions to ensure seamless performance. By doing so, we actively optimize both connectivity and energy efficiency, allowing the device to operate effectively in real-world scenarios.

Leveraging Internal Expertise and Proven Designs

With years of R&D and a library of proven designs, we accelerate development while ensuring reliability. This foundation allows us to:

- Deliver faster time to market

- Ensure designs are certification-ready

- Reduce risks during prototyping and scaling

Prototyping and Customer Validation

We build prototypes for customer approval before committing to larger production. This stage allows clients to test functionality, user experience, and integration with their systems. Any refinements are incorporated before we move to small-batch manufacturing.

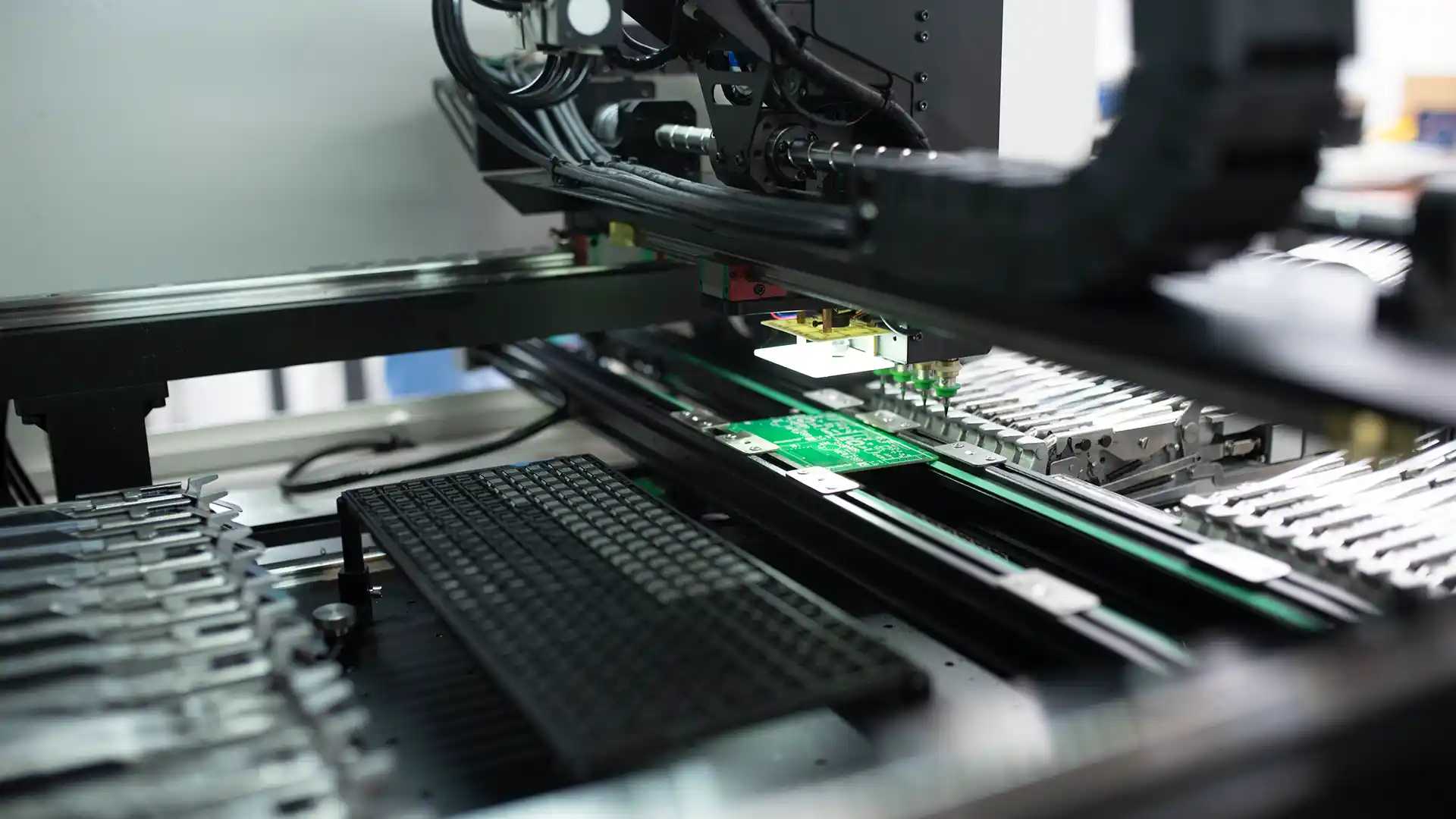

Pilot Manufacturing: 10–100 Units

Thanks to our in-house pick-and-place machines and reflow ovens, we can produce pilot batches quickly. Typically, we begin with 10 units to validate manufacturability. This helps us:

- Spot potential assembly challenges

- Adjust design for easier large-scale production

- Provide working samples for field testing

Certification and Compliance

While pilot runs are underway, certification begins. Devices are sent to accredited labs for compliance testing, covering:

- Safety

- EMC/EMI standards

- Radio/communication approvals

Certification is often the longest part of the process, but we plan it in parallel to avoid delays in launch.

Advanced In-House Manufacturing Capabilities

What sets NORVI apart is the breadth of our in-house production tools and skilled workforce:

- UV Printing for crisp, clear, and professional branding on enclosures.

- Fiber Laser Cutting for precision-cut parts and components.

- CNC Milling Machines for professional-quality window and enclosure modifications.

- Laser Marking Machines for durable, high-contrast product marking and traceability.

- Talented Assembly Team ensuring every product is built with care and consistency.

These capabilities enable us to not only design but also deliver highly customized, production-ready hardware without relying heavily on external vendors. Consequently, we achieve faster turnaround times, maintain higher quality, and gain greater control over the final product. In addition, this approach allows us to respond quickly to changes and continuously optimize the production process.

Scaling to Mass Production

Once all approvals are in place, we then move to mass production, gradually scaling in batches of 100 to 1,000 units. During this phase, our manufacturing process not only ensures consistency but also provides traceability and rigorous quality control. As a result, we can reliably deliver high-quality IoT devices at scale.

Final Thoughts

End-to-end IoT product development is a journey that blends technical expertise, agile prototyping, and manufacturing excellence. By working through these structured stages, we ensure every product is:

- Customer-focused

- Reliable and certifiable

- Scalable from prototype to thousands of units

At NORVI, we’re proud to help businesses transform ideas into market-ready IoT solutions with speed, precision, and unmatched in-house capability. Whether you’re starting by building 10 prototypes or gradually scaling up to 1,000 units, we have both the expertise and the facilities to make it happen seamlessly. Moreover, our team manages each step from initial testing to full scale production efficiently and reliably.

Share this with others:

Got Questions?

For any technical assistance or inquiries, please contact our technical team at support@norvi.io. We are happy to assist you.