Custom IoT Development: The Complete Guide to Building Tailored Industrial IoT Solutions in 2025

What is Custom IoT Development?

Custom IoT development creates connected devices and systems engineered specifically for your business requirements. Unlike generic off-the-shelf products, custom IoT solutions integrate proprietary sensors, embedded systems, cloud platforms, and analytics dashboards designed around your operational workflows, compliance requirements, and strategic objectives.

Furthermore, custom development delivers end-to-end control over hardware selection, firmware programming, data architecture, and security protocols. Consequently, businesses achieve precise functionality that addresses unique challenges rather than adapting workflows to accommodate pre-built limitations.

Why Businesses Choose Custom Product Development Over Ready-Made IoT Devices

The Limitations of Off-the-Shelf Solutions

Off-the-shelf IoT devices serve general markets effectively. However, they consistently fail when businesses require specialized data collection, proprietary protocol integration, or industry-specific compliance standards. Additionally, these products force companies into restrictive vendor ecosystems with limited customization options.

The Strategic Advantage of Tailored IoT Solutions

Custom IoT product development delivers competitive differentiation through:

- Precise Functionality Alignment – Every sensor, communication protocol, and data point matches your exact operational needs. Therefore, you eliminate unnecessary features while enhancing critical capabilities.

- Seamless Legacy System Integration – Custom solutions bridge connections between modern IoT infrastructure and existing industrial equipment, SCADA systems, or enterprise software without middleware compromises.

- Proprietary IP Protection – Moreover, custom development protects your competitive advantages by keeping unique algorithms, data models, and process optimizations proprietary rather than exposing them through third-party platforms.

- Scalability Without Vendor Lock-In – You control expansion paths, component sourcing, and technology evolution instead of depending on vendor roadmaps or facing forced upgrades.

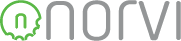

The Complete Custom IoT Product Development Lifecycle

Step 01: Ideation & Concept

Successful embedded product development services begin with crystallizing your vision into a concrete roadmap. During this foundational phase, development teams collaborate with stakeholders to:

- Define the core problem your IoT solution will solve

- Identify specific pain points requiring automation or monitoring

- Establish measurable success criteria and KPIs

- Determine critical data points for decision-making

- Assess technical feasibility and potential roadblocks

- Outline budget parameters and expected ROI

Consequently, this ideation phase prevents costly redesigns and ensures alignment between technical capabilities and business objectives. Moreover, thorough concept validation identifies potential challenges early, allowing teams to adjust strategies before significant investment.

Step 02: Prototyping

Industrial IoT product development advances through iterative prototyping that transforms concepts into tangible proof-of-concept models. Engineers build functional prototypes demonstrating core capabilities and validating technical assumptions. This phase includes:

- Initial circuit board design and breadboard testing

- Component selection and compatibility verification

- Basic firmware development for embedded systems

- Preliminary cloud connectivity tests

- User interface mockups for monitoring dashboards

- Power consumption analysis and optimization

Additionally, prototype testing reveals integration challenges, connectivity limitations, or design flaws before committing to expensive manufacturing tooling. Therefore, rapid iteration during prototyping significantly reduces downstream risks and costs.

Step 03: Hardware Engineering

Following successful prototyping, hardware engineering teams refine designs for production readiness. This critical phase transforms functional prototypes into manufacturable products through:

- Circuit Design Optimization – Engineers finalize PCB layouts, optimize component placement, and minimize board size while ensuring signal integrity and electromagnetic compatibility.

- Enclosure Design – Industrial designers create housings that protect electronics from environmental factors while maintaining accessibility for installation and maintenance. Furthermore, enclosures must meet IP ratings for dust and water resistance appropriate to deployment environments.

- Sensor Integration – Teams select and integrate sensors matched to accuracy requirements, operating conditions, and cost constraints. Consequently, proper sensor selection ensures reliable data collection across temperature ranges, humidity levels, and mechanical stresses.

- Power System Design – Engineers optimize power consumption, select appropriate battery technologies, and design charging circuits or energy harvesting systems for long-term autonomous operation.

- Design for Manufacturing (DFM) – Moreover, hardware designs undergo DFM reviews ensuring reliable mass production while controlling costs through appropriate component selection and assembly processes.

Step 04: Firmware Development

Embedded software development brings hardware to life through sophisticated firmware programming. This phase encompasses:

- Low-Level Programming – Developers write firmware controlling hardware peripherals, managing sensors, and implementing communication protocols. Therefore, efficient code ensures optimal device performance and power consumption.

- Communication Stack Implementation – Teams integrate WiFi, cellular, LoRaWAN, or industrial protocol stacks enabling reliable connectivity under varying network conditions. Additionally, firmware handles connection management, retry logic, and offline buffering.

- Security Implementation – Robust firmware includes secure boot mechanisms, encrypted storage, certificate management, and over-the-air (OTA) update capabilities protecting devices from cyber threats.

- Edge Processing Logic – Furthermore, firmware implements local data processing, filtering, and decision-making reducing cloud dependency and enabling real-time responses to critical events.

- Power Management – Developers optimize sleep modes, implement intelligent duty cycling, and manage peripheral power states maximizing battery life for remote deployments.

Step 05: Cloud Integration

Cloud platform development creates the backend infrastructure for data management, analytics, and user interaction. This comprehensive phase includes:

- Data Pipeline Architecture – Engineers design scalable ingestion systems handling data from thousands of devices simultaneously. Consequently, proper architecture ensures reliability even during peak loads or network disruptions.

- Database Design – Teams implement time-series databases optimized for IoT data patterns, enabling efficient storage and rapid querying of historical sensor readings.

- API Development – RESTful APIs and WebSocket connections provide secure interfaces for device communication, third-party integrations, and application development.

- Analytics Platform – Moreover, cloud systems implement real-time analytics, machine learning models, and alert engines transforming raw data into actionable insights.

- Dashboard Development – User-facing web and mobile applications provide intuitive interfaces for data visualization, device management, system configuration, and report generation.

- Security & Compliance – Furthermore, cloud infrastructure implements encryption, access controls, audit logging, and compliance frameworks meeting industry-specific regulatory requirements.

Step 06: Testing & QA

Comprehensive quality assurance ensures devices perform reliably under real-world conditions. This rigorous phase encompasses:

- Functional Testing – Verification that all hardware components, sensors, and firmware features operate according to specifications across operating temperature ranges and power conditions.

- Integration Testing – Teams validate end-to-end workflows including device connectivity, data transmission, cloud processing, and user interface functionality. Therefore, integration testing catches system-level issues invisible during component testing.

- Performance Testing – Load testing verifies cloud infrastructure handles anticipated device populations and data volumes. Additionally, teams assess device battery life under realistic usage patterns.

- Security Testing – Penetration testing, vulnerability scanning, and code analysis identify potential security weaknesses before deployment. Moreover, testing validates encryption, authentication, and authorization mechanisms.

- Environmental Testing – Devices undergo temperature cycling, humidity exposure, vibration testing, and ingress protection verification ensuring reliability in deployment environments.

- Certification Testing – Furthermore, products complete FCC, CE, UL, or industry-specific certification testing required for legal market entry and customer acceptance.

Step 07: Deployment & Scaling

The final phase transitions solutions from development into production environments with strategies ensuring smooth adoption and long-term success. This includes:

- Pilot Deployment – Initial limited rollouts validate system performance in real operating conditions while minimizing risk. Consequently, pilot programs provide valuable feedback informing full-scale deployment strategies.

- Installation Planning – Teams develop detailed procedures for device installation, network configuration, and system commissioning minimizing operational disruption during rollout.

- User Training – Comprehensive training programs ensure operators, maintenance personnel, and administrators understand system capabilities, monitoring procedures, and troubleshooting protocols.

- Manufacturing Scaling – Production ramps from initial pilot quantities to full-scale manufacturing volumes. Therefore, supply chain management and quality control processes scale proportionally maintaining consistent product quality.

- Ongoing Support & Evolution – Moreover, successful deployments include continuous monitoring, firmware updates, feature enhancements, security patches, and technical support ensuring systems deliver value throughout their operational lifecycle.

- Data-Driven Optimization – Furthermore, analytics from deployed systems inform continuous improvement initiatives, revealing opportunities for efficiency gains, cost reductions, or new capabilities enhancing ROI over time.

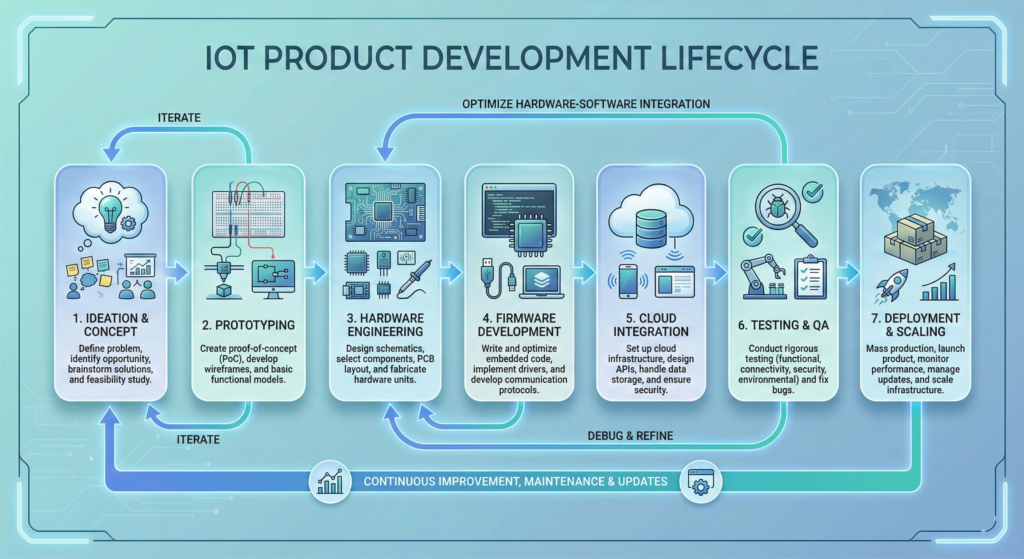

Custom Product Development for Industry 4.0: Enabling Smart Manufacturing

What Makes Industry 4.0 Different

Industry 4.0 represents the fourth industrial revolution, characterized by cyber-physical systems, real-time data exchange, and intelligent automation. Consequently, manufacturing facilities transform into smart factories where machines communicate autonomously, predict maintenance needs, and optimize production dynamically.

How Custom IoT Powers Digital Transformation

Real-Time Production Monitoring – Custom sensors track equipment performance, cycle times, and quality metrics continuously. Therefore, operators identify bottlenecks immediately and adjust production schedules proactively.

Predictive Maintenance Implementation – By analyzing vibration patterns, temperature fluctuations, and operational metrics, custom IoT systems predict equipment failures before they occur. This approach reduces unplanned downtime by up to 50% while extending asset lifecycles.

Supply Chain Visibility – Additionally, IoT-enabled tracking provides real-time visibility into material flows, inventory levels, and logistics operations. This transparency enables just-in-time manufacturing and reduces working capital tied up in excess inventory.

Quality Control Automation – Computer vision systems and inline sensors detect defects during production rather than through end-of-line inspections. Consequently, manufacturers reduce waste, improve yield rates, and maintain consistent quality standards.

Energy Optimization – Smart metering and consumption analytics identify inefficiencies and enable automated energy management. Industrial facilities typically achieve 15-30% energy cost reductions through IoT-driven optimization.

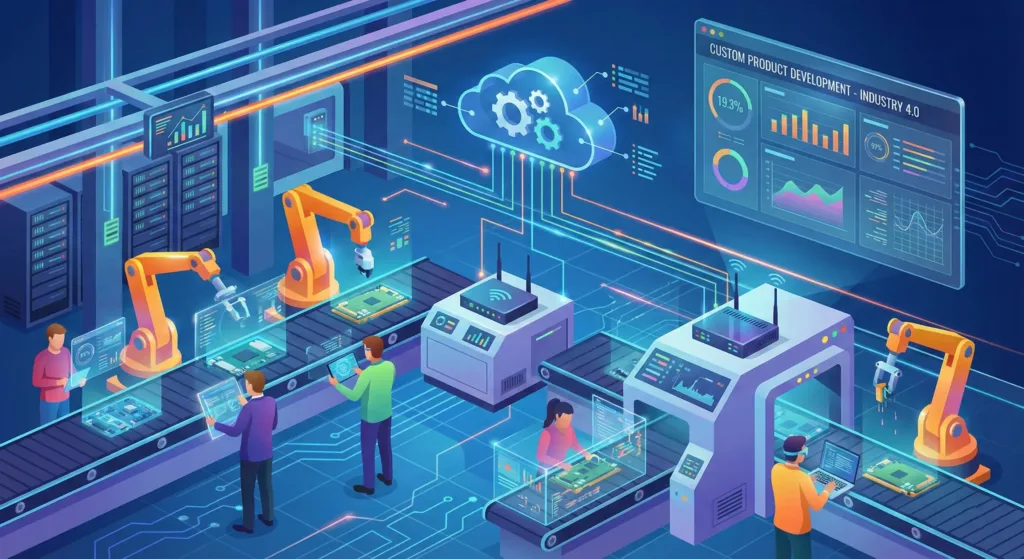

Key Benefits of Custom IoT Development

Operational Excellence

Custom solutions eliminate manual data collection, reduce human error, and accelerate decision-making through real-time visibility. Moreover, automated workflows free employees for higher-value activities requiring human judgment and creativity.

Measurable ROI

Organizations implementing custom IoT solutions typically observe:

- 25-40% reduction in operational costs through efficiency gains

- 30-50% decrease in unplanned downtime via predictive maintenance

- 15-25% improvement in asset utilization through data-driven optimization

- 20-35% reduction in energy consumption from intelligent monitoring

Furthermore, custom development delivers faster payback periods compared to enterprise software implementations because solutions address specific high-impact use cases rather than deploying broad platforms requiring extensive configuration.

Competitive Differentiation

Tailored IoT capabilities become strategic assets that competitors cannot easily replicate. Companies leveraging proprietary data insights, automated processes, and optimized operations establish market leadership positions that generic tools cannot provide.

Future-Proof Flexibility

Custom architectures adapt as business requirements evolve. Therefore, companies add new sensors, expand analytics capabilities, or integrate emerging technologies without replacing entire systems—a flexibility impossible with rigid commercial products.

Need Expert Guidance on Your IoT Project?

Transform your concept into reality with our custom IoT development services. Our team specializes in end-to-end product development—from ideation to deployment. Get a free consultation to discuss your requirements, technical feasibility, and projected ROI.

Schedule Your Free ConsultationReal-World Custom IoT Applications Across Industries

Manufacturing: Smart Factory Implementation

A precision manufacturing company installed custom IoT sensors on over 200 machines to continuously monitor key parameters such as spindle vibration, tool wear, and part dimensions. The system automatically adjusted machining settings and scheduled tool replacements based on real-time data. As a result, the company achieved a 35% reduction in scrap materials and a 40% improvement in overall equipment effectiveness (OEE), clearly demonstrating how IoT solutions can optimize operations and deliver tangible results in real-world industrial settings.

Logistics: Fleet Management and Asset Tracking

A logistics provider developed custom GPS trackers equipped with environmental sensors to monitor temperature-sensitive cargo in real time. The system provided live location updates, temperature alerts, and predictive arrival times. As a result, the company reduced spoilage by 60% and enhanced customer satisfaction by providing accurate delivery windows, showing how IoT solutions can optimize logistics and protect sensitive shipments in real-world operations.

Healthcare: Remote Patient Monitoring

A healthcare organization developed custom wearable devices to monitor vital signs of patients with chronic diseases. The devices continuously transmitted real-time data to clinicians, allowing for early interventions before conditions worsened. As a result, the organization reduced hospital readmissions by 45% and improved patient outcomes, demonstrating how IoT solutions can transform healthcare delivery in real-world applications.

Agriculture: Precision Farming Systems

An agricultural operation deployed custom soil moisture sensors, weather stations, and automated irrigation controllers across thousands of acres. The system adjusted water usage based on crop needs and environmental conditions, resulting in a 40% reduction in water consumption and a 25% increase in crop yields, illustrating how IoT solutions can drive sustainable and efficient farming in real-world applications.

Energy: Smart Grid Management

A utility company implemented custom IoT meters and grid sensors to enable real-time load balancing, outage detection, and predictive maintenance. The system enhanced grid reliability by 30% and supported dynamic pricing programs that reduced peak demand by 15%, demonstrating how IoT solutions can optimize energy management and improve operational efficiency in real-world utility operations.

Ready to Build Your Custom IoT Solution?

Stop compromising with off-the-shelf products. Partner with IoT experts who understand your industry challenges. From hardware design to cloud integration, we deliver tailored solutions that drive measurable ROI.

Experienced in Manufacturing, Healthcare & Logistics | Full-Stack Development: Hardware + Firmware + Cloud | Proven Track Record with Industry 4.0 Implementations

Start Your Project TodayEmbedded Product Development Services: What to Expect from Your Development Partner

Core Technical Capabilities

Professional IoT development firms provide comprehensive expertise spanning:

- Hardware Engineering – Circuit design, component selection, PCB layout, thermal management, and ruggedization for harsh environments.

- Embedded Software Development – Firmware programming, real-time operating systems, device drivers, and communication protocol implementation.

- Cloud Architecture – Scalable data platforms, API development, database design, and analytics pipeline implementation.

- Security Implementation – Moreover, encryption protocols, secure boot mechanisms, certificate management, and vulnerability testing protect connected devices from cyber threats.

- Mobile and Web Development – User-facing applications providing intuitive interfaces for device management, data visualization, and system configuration.

Project Management and Collaboration

Successful partnerships employ agile methodologies with regular sprints, frequent stakeholder reviews, and continuous integration testing. Therefore, clients maintain visibility into progress while providing feedback that shapes development priorities.

Post-Launch Support

Comprehensive services include firmware update management, bug fixes, feature enhancements, cloud infrastructure monitoring, and technical support. Additionally, development partners often provide training, documentation, and knowledge transfer ensuring internal teams can manage systems effectively.

Choosing Between Custom Development and Commercial IoT Platforms

When Custom Development Makes Sense

Choose custom IoT product development when:

- Your requirements differ significantly from standard market offerings

- You need proprietary features protecting competitive advantages

- Existing systems require deep integration with legacy protocols

- Industry-specific compliance mandates exceed commercial product capabilities

- Long-term total cost of ownership favors purpose-built solutions over subscription platforms

- You require complete data ownership without third-party dependencies

When Commercial Solutions Suffice

Consider off-the-shelf products when:

- Your requirements match standard functionality without customization

- Speed to market outweighs strategic differentiation

- Budget constraints limit custom development investment

- Internal technical resources cannot support custom system maintenance

- Your use case involves well-established IoT applications with proven commercial solutions

Emerging Trends in Custom IoT Development

AI and Machine Learning Integration

Custom IoT systems increasingly incorporate edge AI capabilities enabling real-time decision-making without cloud connectivity. Consequently, devices perform complex analytics locally, reducing latency while enhancing privacy and reliability.

5G Connectivity

Next-generation cellular networks enable high-bandwidth, low-latency applications previously impossible with existing infrastructure. Therefore, custom IoT solutions leverage 5G for video analytics, augmented reality maintenance guidance, and time-critical industrial control systems.

Digital Twin Technology

Furthermore, organizations create virtual replicas of physical assets using IoT sensor data. These digital twins enable simulation, optimization, and predictive modeling that improve operational performance before implementing changes in production environments.

Blockchain for Supply Chain Transparency

Custom IoT systems combined with blockchain create immutable records of product provenance, quality certifications, and custody chains. This capability proves essential for industries requiring verified traceability like pharmaceuticals, food safety, and luxury goods.

Security Considerations in Custom IoT Development

Device-Level Security

Robust embedded product development services implement multiple security layers:

- Secure boot processes preventing unauthorized firmware installation

- Hardware encryption modules protecting sensitive data at rest

- Certificate-based authentication ensuring only authorized devices connect to networks

- Regular security patches addressing newly discovered vulnerabilities

Network Security

Additionally, custom solutions employ network segmentation, VPNs, and intrusion detection systems isolating IoT devices from corporate networks while enabling necessary data flows.

Cloud Security

Moreover, comprehensive security frameworks include data encryption in transit and at rest, role-based access controls, audit logging, and compliance with standards like SOC 2, ISO 27001, or HIPAA depending on industry requirements.

Cost Considerations for Custom IoT Projects

Development Investment

Custom IoT development typically requires upfront investment ranging from $50,000 for simple prototypes to several million dollars for complex industrial systems with extensive deployments. However, this investment delivers long-term value through:

- Elimination of recurring licensing fees charged by commercial platforms

- Reduced operational costs through efficiency gains and automation

- Competitive advantages generating revenue growth

- Ownership of intellectual property enhancing company valuation

Total Cost of Ownership

Furthermore, realistic budgeting includes ongoing expenses:

- Cloud infrastructure hosting and data storage

- Cellular connectivity for devices using wireless networks

- Firmware maintenance and security updates

- Technical support and system monitoring

- Hardware refresh cycles as technology evolves

Consequently, thorough financial analysis comparing custom development against commercial alternatives should evaluate 5-10 year total cost of ownership rather than initial purchase prices alone.

Getting Started with Your Custom IoT Initiative

Define Clear Objectives

Successful projects begin with specific, measurable goals. Therefore, articulate exactly what business outcomes you expect-reduced downtime, improved quality, cost savings, or revenue growth—along with quantitative targets.

Assess Internal Capabilities

Moreover, evaluate whether your organization possesses technical expertise for long-term system management or requires ongoing vendor support. This assessment shapes development partner selection and contract structures.

Start With Pilot Projects

Rather than enterprise-wide deployments, launch focused pilots demonstrating value quickly while minimizing risk. Successful pilots build organizational support and provide learnings that inform broader rollouts.

Choose the Right Development Partner

Finally, select partners based on:

- Relevant industry experience and reference projects

- Technical expertise across hardware, firmware, cloud, and security

- Project management methodologies ensuring transparency and accountability

- Post-launch support capabilities for ongoing maintenance and enhancement

Conclusion: Transform Your Operations with Custom IoT Solutions

Custom IoT development represents strategic investment in operational excellence, competitive differentiation, and digital transformation. Unlike generic products forcing compromises, tailored solutions deliver precise capabilities addressing your unique challenges while providing flexibility for future evolution.

Furthermore, organizations embracing custom IoT approaches achieve measurable results, reduced costs, improved efficiency, enhanced quality, and new revenue opportunities, that generic tools cannot match. As Industry 4.0 accelerates and connected technologies become foundational to competitive advantage, custom development transitions from optional enhancement to business imperative.

Ready to explore how custom IoT development can transform your operations? Contact our embedded product development team for a strategic consultation assessing your requirements, technical options, and potential ROI. We’ll help you navigate the journey from concept through deployment, ensuring your investment delivers lasting value.

Looking for expert guidance on industrial IoT product development? Our team specializes in custom solutions for manufacturing, logistics, healthcare, and energy industries. Schedule a discovery call to discuss your specific requirements and explore how tailored IoT technology can drive your digital transformation.

Share this with others:

Got Questions?

For any technical assistance or inquiries, please contact our technical team at support@norvi.io. We are happy to assist you.