Replacing PLCs with NORVI X – Cost & Flexibility for Modern Automation

Traditional programmable logic controllers have dominated industrial automation for decades. However, rising costs and limited flexibility are pushing manufacturers to explore alternatives. The NORVI X controller represents a new generation of industrial automation solutions that combine PLC reliability with IoT connectivity and modular scalability.

This comprehensive guide explores why businesses are replacing traditional PLCs with the NORVI X controller, examining cost savings, flexibility advantages, and real-world applications. Whether you’re an automation engineer evaluating alternatives or a plant manager seeking ROI improvements, understanding this shift toward Industrial IoT controllers can transform your automation strategy.

Why Traditional PLCs Limit Modern Automation

Many manufacturing facilities still rely on legacy PLC systems that, while reliable, create significant operational and financial constraints. Understanding these limitations helps explain why forward-thinking organizations are transitioning to more flexible solutions.

High Hardware & Licensing Costs

Traditional PLC systems demand substantial upfront investment. Entry-level compact PLCs typically cost between $200-$600, while mid-sized systems range from $800-$3,000. High-end modular platforms like Rockwell ControlLogix or Schneider Quantum can exceed $5,000 for the hardware alone.

Beyond hardware expenses, proprietary programming software adds another layer of cost. Software licenses can range from $500 to several thousand dollars annually, creating ongoing financial commitments. Moreover, expanding these systems requires purchasing additional modules at premium prices, often with long lead times.

Limited I/O and Scalability

Most traditional PLCs offer fixed input/output configurations that cannot easily adapt to changing production requirements. When manufacturers need additional sensing points or actuator connections, they face expensive hardware upgrades or complete system replacements.

Scalability challenges become particularly acute during facility expansions. Adding just a few extra sensors may require purchasing an entirely new PLC rack or module, with costs disproportionate to the actual functionality needed. Consequently, many facilities operate with oversized systems purchased for future growth that may never materialize.

Vendor Lock-In and Proprietary Software

Perhaps the most frustrating limitation involves vendor dependency. Each PLC manufacturer uses proprietary programming environments and communication protocols. Switching vendors requires retraining staff, replacing hardware, and rewriting control programs—a process that can cost hundreds of thousands of dollars for mid-sized facilities.

This lock-in extends to maintenance and spare parts. Discontinued models leave facilities scrambling for compatible replacements, often at inflated prices from limited suppliers. Additionally, integrating multiple PLC brands within a single facility creates programming nightmares and communication challenges.

What Makes NORVI X a PLC Alternative?

The NORVI X represents a fundamental rethinking of industrial control systems, addressing the pain points that plague traditional PLCs while maintaining industrial-grade reliability.

Modular Design and Expansion Capabilities

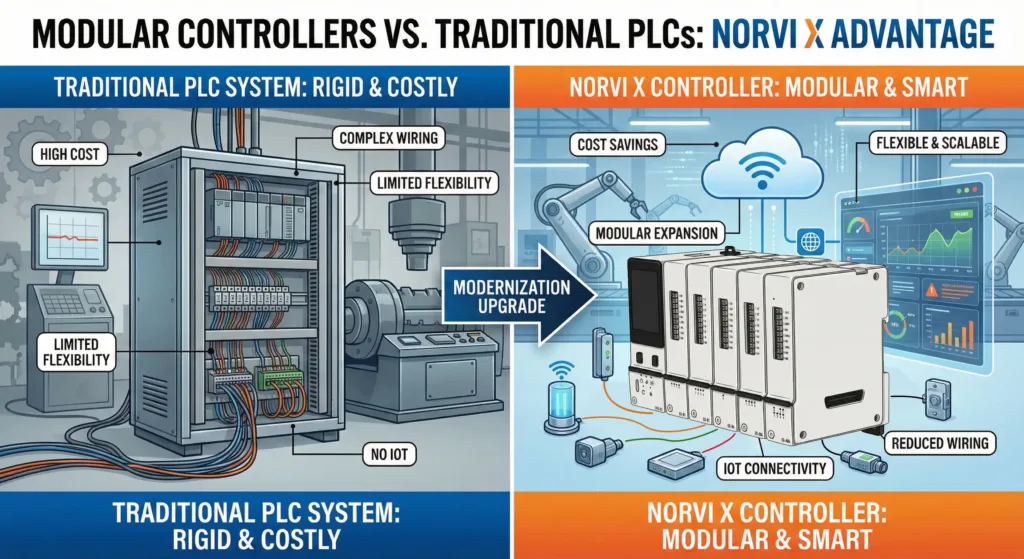

📚 Documentation Tip: Visit the NORVI X datasheet for complete technical specifications and GPIO pin assignments.

Unlike fixed-configuration PLCs, NORVI X features a modular architecture built around a powerful CPU module that accepts plug-and-play expansion modules. The system scales from basic applications to complex installations supporting up to 200 inputs and outputs.

This modularity provides unprecedented flexibility:

- Add I/O as needed: Purchase only the inputs and outputs required for current needs, then expand gradually

- Mix signal types: Combine digital inputs, analog sensors, relay outputs, and transistor outputs in any configuration

- Hot-swappable modules: Replace or add modules without extensive downtime or system reconfiguration

- Communication expansions: Add LoRa, NB-IoT, or additional Ethernet ports as connectivity requirements evolve

The expansion modules connect via I2C and UART interfaces, ensuring reliable communication while simplifying wiring. Each module integrates seamlessly with the CPU through standardized connectors, eliminating custom integration work.

Industrial Protocol Support (Modbus, MQTT, OPC-UA)

The NORVI X speaks the language of both legacy industrial equipment and modern IoT platforms. Built-in protocol support includes:

- Modbus RTU/TCP: Connect seamlessly with existing sensors, drives, and industrial instruments

- MQTT: Publish data to cloud platforms and enterprise systems with minimal latency

- HTTP/HTTPS: Enable web-based monitoring and RESTful API integration

- OPC-UA: Facilitate interoperability with SCADA systems and enterprise manufacturing software

This multi-protocol capability eliminates the need for expensive protocol converters or gateway devices. A single NORVI X controller can simultaneously communicate with legacy Modbus equipment, publish data to cloud analytics platforms via MQTT, and provide OPC-UA interfaces for enterprise systems.

Furthermore, the open-source firmware architecture allows engineers to implement custom protocols when needed, something virtually impossible with proprietary PLC systems.

Edge Computing and IoT Connectivity

Traditional PLCs excel at real-time control but struggle with data processing and cloud connectivity. NORVI X bridges this gap by integrating edge computing capabilities directly into the controller.

The ESP32-based architecture provides sufficient processing power to:

- Perform local data analytics and filtering before cloud transmission

- Execute machine learning inference for predictive maintenance

- Log data locally to microSD cards, reducing cloud storage costs

- Implement complex logic and computational tasks beyond simple ladder logic

Connectivity options include Ethernet, Wi-Fi, Bluetooth, and cellular (via expansion modules), ensuring reliable communication regardless of infrastructure availability. The built-in DS3231 real-time clock with battery backup maintains accurate timestamps even during power outages, crucial for regulatory compliance and data integrity.

Cost Comparison: PLC vs NORVI X

Understanding the true cost difference requires looking beyond initial purchase prices to examine total cost of ownership over a typical five-year deployment.

Hardware and Installation Costs

| Traditional PLC | NORVI X |

|---|---|

| PLC hardware: $1,500-$2,500 | NORVI X CPU module: $70.00-$100.00 |

| I/O expansion modules: $800-$1,200 | Expansion modules (equivalent I/O): $12.00-$80.00 |

| Programming cable/interface: $200-$400 | Standard USB programming cable: $5-$15 |

| Power supply and mounting hardware: $300-$500 | DIN-rail mounting (included): $0 |

| Total hardware cost: $2,800-$4,600 | Total hardware cost: $200-$700 |

The hardware savings alone represent 75-85% reduction in initial investment. Moreover, installation costs decrease because NORVI X uses standard DIN-rail mounting and simplified wiring schemes.

Maintenance and License Savings

Ongoing costs reveal even more dramatic differences:

| Traditional PLC | NORVI X |

|---|---|

| Software license renewals: $300-$1,000 | Software licenses: $0 (open-source tools) |

| Technical support contracts: $500-$2,000 | Programming environment: $0 (Arduino IDE, ESP-IDF) |

| Proprietary programming tools: $200-$500 | Community support: $0 (active developer community) |

| Training and certification: $1,000-$3,000 | Training: $0-$500 (extensive online resources) |

| Annual total: $2,000-$6,500 | Annual total: $0-$500 |

Over five years, maintenance cost savings exceed $10,000-$30,000 per controller, often enough to fund entire facility upgrades.

Total Cost of Ownership (TCO)

Calculating TCO over five years reveals the compelling economics:

| Traditional PLC System | NORVI X System |

|---|---|

| Initial hardware: $3,500 | Initial hardware: $700 |

| Installation labor: $1,500 | Installation labor: $800 |

| Software/licensing (5 years): $5,000 | Software/licensing (5 years): $0 |

| Training: $4,000 | Training: $500 |

| Expansion/upgrades: $2,000 | Expansion/upgrades: $100 |

| 5-Year TCO: $16,000 | 5-Year TCO: $2100 |

The NORVI X delivers an 84% reduction in total cost of ownership. For facilities with multiple control points, these savings multiply quickly. A manufacturing facility replacing just ten PLC stations could save over $135,000 in five years.

Flexibility & Scalability Benefits of NORVI X

Cost savings alone don’t tell the complete story. The architectural differences between traditional PLCs and NORVI X create operational advantages that improve competitiveness and agility.

Modular I/O Expansion

Unlike PLCs requiring specific expansion modules from a single vendor, NORVI X supports diverse expansion options:

- 16-bit analog input modules: High-precision 0-10V and 4-20mA inputs for process control

- Analog output modules: 12-bit resolution for proportional valve control

- Digital input expansions: Optically isolated inputs for sensor integration

- Transistor output modules: Control 24V DC loads with MCP23017 I/O expanders

- Relay output modules: Switch loads up to 5A at 250VAC

- Specialized sensors: Thermocouple, RTD, and load cell interfaces

All expansion modules use standardized I2C addressing, allowing engineers to create custom configurations without programming complexity. Address configurability prevents conflicts when using multiple modules of the same type.

This flexibility proves invaluable when retrofitting legacy equipment. Engineers can match the exact sensor and actuator types already installed, avoiding costly equipment replacements just to accommodate controller limitations.

Retrofitting Legacy Machines

Older manufacturing equipment often uses perfectly functional sensors and actuators that simply need modern control and connectivity. NORVI X excels in these retrofit scenarios:

Facilities can maintain existing field wiring while gaining modern capabilities like remote monitoring, data logging, and cloud connectivity. The multi-protocol support means legacy Modbus devices continue functioning alongside new MQTT-enabled sensors.

One common retrofit scenario involves packaging machines with relay-based control panels. Replacing the relay logic with NORVI X provides:

- Programmable logic that can be modified without rewiring

- Data collection capabilities for OEE (Overall Equipment Effectiveness) tracking

- Remote access for troubleshooting and parameter adjustments

- Predictive maintenance alerts based on cycle counting and runtime

The DIN-rail mounting allows NORVI X to fit in existing control panels, often in the same footprint as the relay bank it replaces.

Fast Deployment and Prototyping

Time-to-market pressures demand rapid development cycles. NORVI X dramatically accelerates automation project timelines:

Development teams can prototype control systems on a desktop using the same hardware that will eventually deploy to production. The USB programming interface and familiar Arduino IDE eliminate the need for specialized programming hardware and training.

Changes and updates deploy in minutes rather than hours. During commissioning, engineers can modify control logic, test, and reload programs without waiting for PLC compilation cycles. OTA (Over-The-Air) firmware updates enable remote upgrades without site visits.

This agility extends to testing and validation. Engineers can build multiple prototype stations in parallel for less than the cost of a single traditional PLC development system. Testing different control strategies or sensor configurations becomes economically feasible.

Real-World Use Cases: Modernizing Legacy PLC Systems

Practical examples demonstrate how organizations are successfully deploying NORVI X as a PLC replacement across various industries.

Manufacturing Assembly Lines

A mid-sized electronics manufacturer faced challenges with aging PLCs controlling a circuit board assembly line. The existing system required expensive maintenance contracts and lacked data collection capabilities needed for quality tracking.

The Solution:

Engineers replaced five PLCs with NORVI X controllers configured with:

- 32 digital inputs monitoring station status and safety interlocks

- 16 relay outputs controlling conveyors and workstation equipment

- 8 analog inputs tracking temperature and pressure in soldering stations

- Ethernet connectivity to factory MES system

- Local data logging for quality documentation

Results:

- Hardware costs reduced by 78%

- Installation completed in three weekends vs. projected two-month PLC replacement timeline

- Real-time production data enabled OEE improvements of 15%

- Remote monitoring reduced troubleshooting site visits by 60%

The programmable logic provided flexibility to adjust cycle times and add new quality checks without vendor involvement or costly programming tools.

Packaging & Conveyor Systems

A food packaging facility operated multiple conveyor lines controlled by different PLC brands from various acquisition periods. This created maintenance nightmares and prevented integrated production scheduling.

The Solution:

NORVI X controllers standardized control across all lines while maintaining compatibility with existing sensors and drives:

- Modbus RTU interfaces communicated with legacy variable frequency drives

- Digital inputs monitored photo sensors and proximity switches

- Relay outputs controlled pneumatic diverters and reject mechanisms

- MQTT connectivity published production counts to central monitoring system

Results:

- Standardization reduced spare parts inventory by 40%

- Unified programming environment cut troubleshooting time by 50%

- Real-time production visibility improved scheduling efficiency

- System paid for itself in 11 months through maintenance savings alone

The facility now trains operators on a single control platform rather than maintaining expertise across multiple proprietary systems.

SME Factory Automation

A small machine shop with 15 CNC machines struggled with manual data collection and inconsistent process monitoring. Traditional PLC solutions exceeded their budget and required expertise they didn’t have in-house.

The Solution:

NORVI X controllers deployed at each machine with:

- Digital inputs monitoring machine status (running, idle, alarm)

- Analog inputs tracking spindle load and coolant levels

- Cellular IoT expansion modules for machines without Ethernet access

- Cloud MQTT connectivity for centralized monitoring dashboard

Results:

- Total implementation cost 1/5th of quoted PLC system

- Engineering team programmed controllers using online Arduino tutorials

- Real-time machine monitoring identified 2.5 hours daily idle time

- Predictive alerts for coolant levels reduced unplanned stoppages by 30%

The open-source ecosystem allowed the shop to customize monitoring screens and reporting without expensive SCADA software licenses.

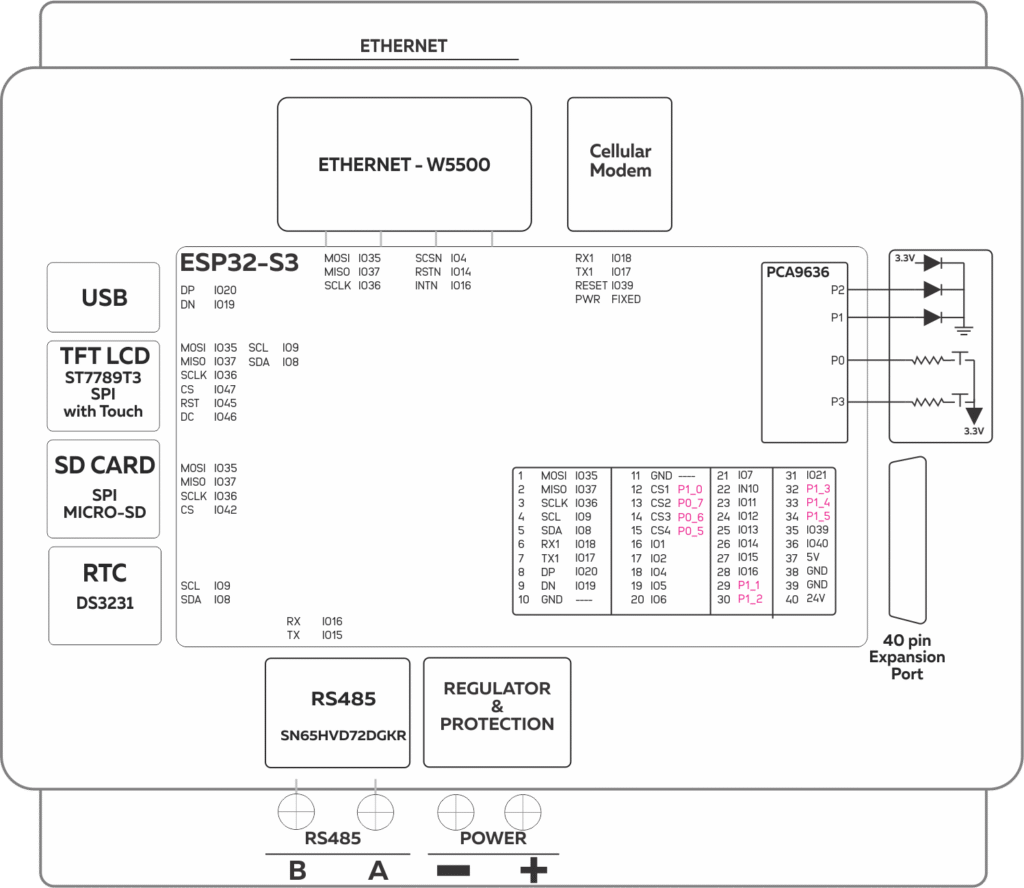

When to Choose NORVI X Over a PLC

While NORVI X offers compelling advantages, understanding optimal application scenarios ensures successful deployments.

Decision Criteria for Engineers and Managers

Choose NORVI X when:

- Budget constraints limit traditional PLC investment

- Applications require IoT connectivity and cloud integration

- Flexibility and rapid iteration are priorities

- Integration with diverse protocols is necessary

- In-house programming capability exists or can be developed

- Future expansion requirements are uncertain

- Remote monitoring and data logging are important

- Open-source tools align with organizational philosophy

Consider traditional PLCs when:

- Mission-critical safety systems require certified hardware (SIL-rated applications)

- Industry regulations mandate specific controller certifications

- Existing infrastructure is heavily invested in a particular PLC ecosystem

- Extremely high I/O counts (500+ points) are required

- Microsecond-level real-time response is critical

- Long-term vendor support guarantees are non-negotiable

Hybrid approaches also work effectively. Many facilities use traditional PLCs for safety-critical applications while deploying NORVI X controllers for data collection, non-critical control, and IoT connectivity.

Ideal Industries and Machine Types

NORVI X excels in numerous industrial sectors:

| Manufacturing & Assembly | Food & Beverage | Warehousing & Logistics | Process Industries | Machine Builders & OEMs |

|---|---|---|---|---|

| Pick-and-place machines | Packaging equipment | Sortation systems | Tank level monitoring | Custom automation equipment |

| Assembly line coordination | Batch processing systems | Automated storage/retrieval | Pump control systems | Prototype development |

| Quality inspection stations | Conveyor controls | Dock door controls | Environmental monitoring | Small production runs |

| Material handling systems | Temperature monitoring | Inventory tracking | Energy management | Retrofit projects |

The modular architecture particularly benefits machine builders who need to customize control systems for each customer without maintaining inventory of expensive PLC variants.

ROI and Long-Term Scalability

Return on investment calculations should consider both tangible and intangible benefits:

| Tangible ROI Factors | Intangible Benefits |

|---|---|

| Hardware cost savings (70-85% typical) | Greater programming flexibility |

| Software licensing elimination | Vendor independence |

| Reduced training expenses | Easier recruitment (Arduino skills vs. specialized PLC training) |

| Lower maintenance costs | Accelerated innovation cycles |

| Faster deployment timelines | Improved data visibility |

Most organizations report ROI periods of 6-18 months, depending on application complexity and existing infrastructure. Facilities with multiple automation needs see even faster returns as engineering efficiency improvements compound across projects.

Scalability advantages extend beyond hardware. The growing NORVI ecosystem and active developer community mean solutions and support will continue improving. Organizations investing in NORVI X today are positioning themselves for future automation trends rather than locking into proprietary platforms with uncertain upgrade paths.

Frequently Asked Questions

While NORVI X provides industrial-grade reliability compliant with IEC 61131-2 and EN 61010-1 standards, it is not currently certified for safety-rated (SIL) applications. For safety-critical functions, consider dedicated safety PLCs while using NORVI X for non-safety control and monitoring.

Yes, NORVI X supports Modbus RTU/TCP, OPC-UA, and other industrial protocols, allowing integration with existing PLC systems. It can function as a gateway between legacy equipment and modern IoT platforms.

NORVI X programs using Arduino IDE or ESP-IDF, leveraging C/C++ programming. Engineers’ familiar with structured text or other high-level languages typically adapt quickly. Extensive online resources and community support accelerate learning.

NORVI X features DIN-rail mounting optically isolated I/O, wide voltage input ranges, and industrial-grade components designed for factory environments. Operating temperature ranges and EMC compliance ensure reliable operation in typical industrial conditions.

Industrial-grade components and solid-state design provide longevity comparable to traditional PLCs. The modular architecture means individual components can be replaced without system-wide upgrades. Active development ensures firmware support continues improving.

Conclusion

The evolution from traditional PLCs to Industrial IoT controllers like NORVI X represents more than just cost savings-it signals a fundamental shift in how organizations approach automation. By combining industrial reliability with IoT connectivity, open-source flexibility, and modular scalability, NORVI X addresses the limitations that have constrained traditional automation for decades.

Organizations evaluating PLC alternatives should consider both immediate cost benefits and long-term strategic advantages. The 75-85% reduction in hardware costs and elimination of ongoing license fees provide compelling financial justification. However, the operational benefits, faster deployment, greater flexibility, vendor independence, and superior data capabilities, often deliver even more value over time.

As manufacturing continues its digital transformation journey, control systems must evolve beyond simple logic execution to become data-generating edge computing platforms. NORVI X positions organizations for this future while solving today’s automation challenges.

Ready to explore how NORVI X can transform your automation strategy?

- Contact NORVI for a free consultation

- Download technical specifications and datasheets

- Request a demo unit for evaluation

Share this with others:

Got Questions?

For any technical assistance or inquiries, please contact our technical team at support@norvi.io. We are happy to assist you.